Blog

Determining Flow Characteristics

November 9th, 2021

Your project will depend on a variety of factors, including product flow characteristics and density, fill sizes, container size and configuration, filling times and accuracy. All-Fill provides product testing for customers to receive the most accurate information regarding their product application. By sending us samples of all the products intended to run on one machine as well as containers that will be used, we can provide you with information on your application such as speeds, accuracies, and a suitable machine for your production requirements. Whether you have a new production facility, you have expanded your product range, or you need to replace older equipment, a modern powder filling machine will enhance your operations.

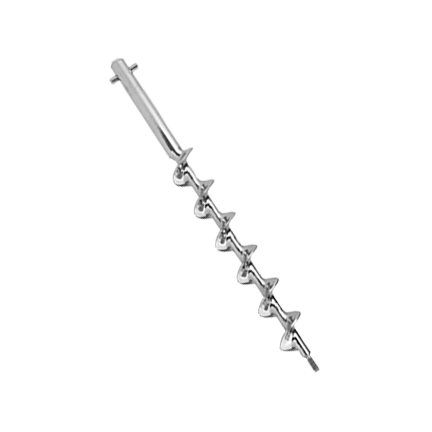

STRAIGHT AUGERSFREE-FLOWING |

|

Free-flow augers, also known as straight augers are made of stainless steel and can be polished to a mirror finish. Straight augers are fabricated with the same outer diameter through the length of the auger allowing the product to meter efficiently and accurately onto the spinner plate or disc. They are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, and more. Our free-flow augers are commonly used with a slow speed or flake blade agitator, a straight funnel, and collector funnel and spinner plate. Products such as, but not limited to, granulated sugar, salt, bread crumbs, and sprinkles are categorized as free flowing products. Usually free flowing products tend to be granules. Most free flow products rely on air displacement in order for the product to drain better, it is very important to vent the collector funnel cover. Dust shrouds are recommended for very dusty granules and most free flow powders. A dust shroud is designed with two separate tubes, one for dispensing product and the other for a dust port to capture airborne product. |

|

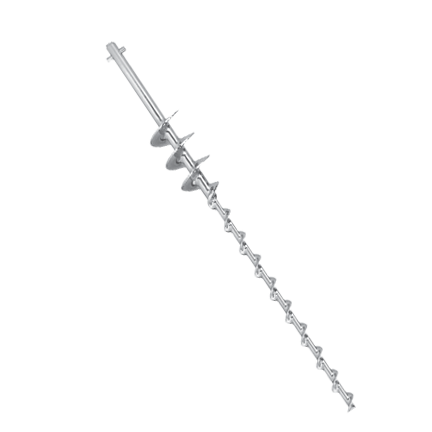

SELF-FEEDING AUGERSNON-FREE-FLOWING |

|

Non-free flowing augers, also known as self-feeding augers are made of stainless steel and can also be polished to a mirror finish. They are used for non-free flowing powders such as bakery mixes, carbon, talcum powder, and others. This type of auger is engineered differently than a straight auger. The top portion of the auger has over-flight. Over-flight is designed to grab and compact product evenly down through the straight section of the auger, dispensing product accurately. A non-free flow product is typically a powder such as pancake mix, flour, ground coffee, protein powders or milk powder. Non-free flow products typically have a certain level of dust associated with them. Non-free flow products require you to use a compression flight auger to gain accuracy. These products can typically be compacted and as appropriately called non-free flow because they will hang up when put on a downward angle. |

|

To learn more or to have your product evaluated, please contact our sister company, Auger Fabrication.

Contact Information: (610) 524-3350 | www.augerfab.com | info@augerfab.com