Blog

KNOWING YOUR AUGER FILLER ACCESSORIES

April 8th, 2014

You might be wondering how to determine what “screw” and “tube” to use on your vertical auger filler. Since 1984, Auger Fabrication has established its name as an industry leader in supplying new and replacement filling accessories. There are two main styles of filling accessories, free-flowing or straight and non-free-flowing or self-feeding. These two styles of accessories are determined through product testing in our facility located in Exton, Pennsylvania. Lab testing is free of charge and is equipped with a full range of augers and funnels that the lab technician can choose from in order to determine the best tooling sizes for our customers. Our augers and funnels are manufactured from a variety of materials such as plastic, stainless steel, and mild steel, with 303 and 304, stainless steel being our “standard”.

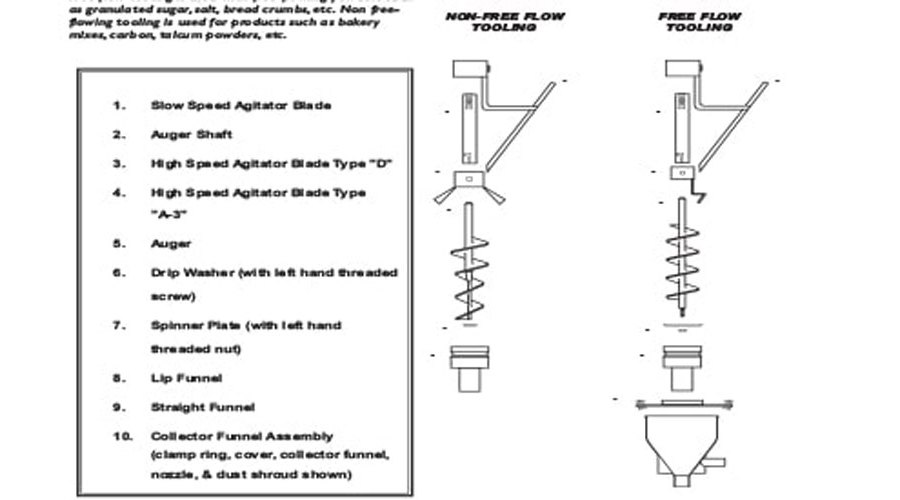

Straight augers (13-1/8” OAL) are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel (5-9/16” OAL), and a collector funnel and spinner plate (figure on the right). All parts are made in-house and designed to meet the delivery of the size auger and funnel combination. A straight auger is most commonly designed /made with common dimensions through the length of the auger. The purpose of this design is to allow the auger to meter product efficiently through the flights of the auger onto a spinner plate or disc. Without the spinner plate, free-flowing products will pass through the auger and funnel. With proper setup, spacing between the end of the funnel and spinner plate, products are dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized and made to spec, to the opening of the customer’s container or bag.

Making sure your vertical auger filler is equipped with the proper filling accessories is the most important aspect of your machine. Send in a sample product for testing or call to discuss your application so that AugerFab, can provide the tooling your machine needs.