Blog

NOT JUST DRY FILLING: ALL-FILL LIQUID PISTON FILLERS

November 30th, 2015

The name says it all, “All-Fill,” meaning that we can in fact fill it all. Although All-Fill is mostly known for our abilities to handle dry filling applications, our versatility working with liquids and pastes should not be overlooked.

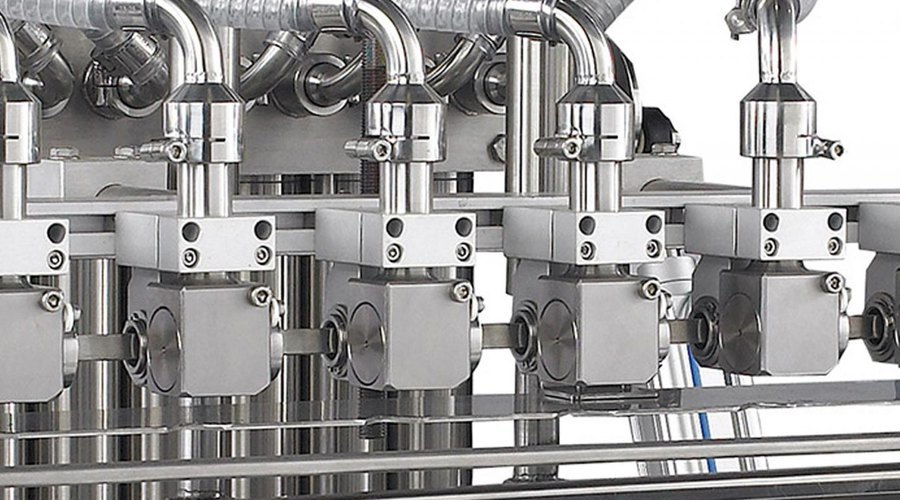

All-Fill rarely gets involved with high speed liquid filling applications but for slow to medium rates we can provide the perfect solution. Just like it is with auger fillers for dry products, liquid filling machines come in both semi-automatic and semi-automatic arrangements. All-Fill liquid fillers are constructed using the highest quality of raw materials with the craftsmanship that All-Fill has been known for over the last 45 years.

The basic semi-automatic liquid filling machine is the model 305. The model 305 is a classified as a volumetric piston filler. The concept is quite simple; there is a holding hopper for which the liquid, cream or paste is held. Below the hopper is a horizontally mounted cylinder. Inside the cylinder there is a piston with a food grade cylinder around it. The piston is pneumatically controlled to retract to the proper distance in order to completely fill the cylinder. Once the cylinder is completely filled with product, the piston is activated to push forward. As the piston presses the product forward a valve is opened below the cylinder which connects to a nozzle that dispenses the product. Depending on the liquid, cream or paste being filled, All-Fill determines the appropriate cut-off device that needs to be used in order to ensure that there is no drip at the end of the fill cycle that can affect volumetric filling accuracy.

A semi-automatic liquid filling machine such as the model 305 piston filler requires an operator to interact with the machine. Most times a foot switch is used to activate the fill cycle, of course, the operator first needs to place the container. With an All-Fill semi-automatic liquid filling machine there is no electricity needed, they are operated solely by compressed air. With that being said, there is always the option to automate the process from semi-automatic to automatic, what this simply means is that a conveyor is integrated with the machine for hands free operation. The operator is replaced by photo-eye sensors and indexing pins and gates. Of course, automated machines have many features but the benefits are typically higher fill rates.

Prior to All-Fill engaging in any discussions regarding liquid filling machines, it is often best to send in container and product samples to All-Fill for testing. All-Fill offers free product testing and during the sample evaluation we are able to best determine the appropriate machine and features needed to give you the fill that you come to expect! A majority of the products filled on All-Fill piston fillers are similar to salsa, thick and thin creams, oils, paints, commercial type solutions and mayonnaise. As you can see, the applications are endless, please let All-Fill Inc. assist with your next liquid filling application. For more information, please contact All-Fill at 610-524-7350 to speak with your local sales representative, we will be happy to hear from you.