GROWTH

1992

THE EARLY 1990’S WAS THE FIRST TIME THAT ALL-FILL BEGAN TO CHANGE AS A RESULT OF THE TECHNOLOGY BOOM THAT WAS SOON TO FOLLOW.

All-Fill’s main offering has always been the semi-automatic auger filler model B-350-e, it is a staple and the backbone of the company. The B-350-e is a clutch brake driven machine; the design has been solid and is still the top quantity seller today in 2016. For those customers that were seeking a bit more precision from their auger filler and more versatility that a machine like the B-350-e could offer, the answer was found with the introduction of the servo motor. The servo motor or simply “servo,” as it has been shortened is a linear actuator that allows for the precise control of position, velocity, and acceleration of the auger when vertically metering products. The servo motor, in conjunction with its own controller or drive, allowed All-Fill to offer a better auger filling machine, albeit at an increased price. “The servo motor was certainly not for everyone, there has and always will be a market for our model B-350-e clutch brake users, but the servo driven auger gives the end user/packager great flexibility. For those with many different and wide-ranging products to package, the servo motor is absolutely the way to go,” said Raymond Arra, sales manager/regional sales manager.

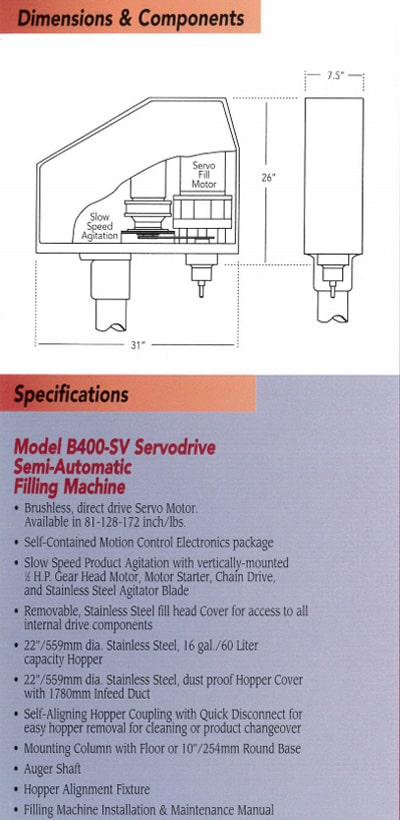

THE SERVO MOTOR WAS PLACED IN THE SAME POSITION AS THE CLUTCH BRAKE, INSIDE THE HEAD CASTING OF THE SEMI-AUTOMATIC FILLING MACHINE.

It was a direct replacement for the clutch brake. The servo motor allowed end users of All-Fill machinery the ability to change the auger fill speed on the fly rather than adjusting a stepped pulley within the fill head/cover. In addition, the acceleration and deceleration profiles of the auger could be adjusted to better handle the various products that need to be metered using an auger. Lastly, the servo motor allowed for precise filling (accuracy) because the auger stopped precisely rather than having to deal with coast compensation with a traditional clutch brake machine. For some, the difference between the clutch brake machine and the servo motor was negligible, but for others it was everything. The servo motor has a built-in encoder that counts the revolutions of the auger, the servo motor was extremely quiet as well, it was most definitely a buzz word and developing trend in the world of packaging machinery.

ALL-FILL FOUND MANY DIFFERENT USES FOR THE SERVO MOTOR. WE USED IT TO CONTROL NOT ONLY THE SEMI-AUTOMATIC AUGER FILLER BUT ALSO THE AUTOMATIC MACHINERY AS WELL.

It was used to control rotary turrets, lift mechanisms, timing screws and much more. When servo motors were first introduced, the price point was of course much higher than it is now 25 years later. The technological advances of the time, mostly centered on the introduction of the servo motor and PLC (programmable logic controller) lead All-Fill into a new realm where the company would be viewed as pioneers of the dry filling industry. All-Fill was always on the cutting edge and bringing new design ideas to the market. “The servo marked a real change at All-Fill. The benefits were obvious; everyone wanted to be working with servos. It was also a challenging time for All-Fill however as there were only a few people in house that could service/assist with the servos at the time,” said Jack Jones (sales manager in 1993). Everyone else had to catch up to the learning curve as the servo motor, drives and PLC was so new to our employees. Since the inception of the servo motor in the early 1990’s, All-Fill has outfitted over 700 auger filling machines with servo motors as the main drive motor and over 450 more for other various uses. Currently the servo motor still holds its place as the most advanced method for accurate filling. The very first All-Fill servo motor auger filling machine was named the Model B-SV-400 and since then many adaptations of the servo filler have come and gone. Today, the standard servo motor fill models are the B-SV-600, SHA-SV-600, DHA-SV-600 and of course the rotary and multi-fill servo motor series machines.