ALL-FILL TEST LAB

Our onsite Testing Lab is a feature that All-Fill provides for free. The Testing Lab allows us to test fill the product into the desired container by finding the best filler for the application.

We Offer Complimentary Product Testing

You name it, there's a good chance we've filled it, or something similar. Your project will depend on a variety of factors, including product flow characteristics and density, fill sizes, container size and configuration, filling times and accuracy. All-Fill provides product testing for customers to receive the most accurate information regarding their product application. By sending us samples of all of the products intended to run on one machine as well as containers that will be used, we can provide you with information on your application such as speeds, accuracies, and a suitable machine for your production requirements.

This free service allows us to determine the best machine, model, and most importantly, tooling for your product and specifications. At All-Fill, we make this process very simple and easy. All-Fill customers are encouraged to send sample product and containers to our facility for evaluation. We strongly recommend that our customers send in their sample products as well as any containers for the products for accurate test results.

Highlight: Test Lab Overview

In addition to sending samples, All-Fill encourages all customers to visit the test lab when running samples. Every time a customer visits the All-Fill test lab, they come away understanding their product characteristics, machinery and tooling better. The lab tests are perfect for customers looking to buy new machinery, improve an existing auger filler installation or customers that simply need new tooling for a new product that they want to introduce to their packaging operation.

"If the users of All-Fill auger fillers took the time to understand their products and to understand all the auger tooling and auger tooling accessories, they can easily improve their packaging operation regarding filling rate, filling accuracy as well as cleanliness and the presentation of their filled product," exclaims Reilley, a long time All-Fill employee. When evaluating your sample products, All-Fill will test a variety of tooling combinations that will yield the best speed and accuracy. The test lab is now run by Chris O'Keefe. Chris has taken over for the recently retired Biff Bailey, who ran the test lab for the last 27 years. O'Keefe has been with the company for the last 8 years and has spent the last year in the lab as Biff's understudy. Chris is excited to continue All-Fill's legacy as the industry leader in product handling experience. All-Fill will continue to find the best solution possible for your applications.

Highlight: All-Fill Test Lab Capabilities

Key Considerations During the Testing Process

- Clearly identify each container you need to fill specifying the type (e.g., bottle, bag, box, etc.). For each container, associate the specific product you intend to fill it with. Ensure you have a detailed list of products matched with their corresponding containers to streamline the filling process and avoid any mix-ups.

- Label the target weight on every application clearly, ensuring that each product has an associated target weight for accuracy. Additionally, create an organized product matrix to illustrate every production run goal comprehensively.

- This product matrix should include:

- – Product Details: The name and type of product to be filled.

- – Container Information: The type of container (e.g., bottle, bag, box) and its dimensions, including opening size.

- – Production Rate: The expected production rate, measured in containers per minute (CPM).

- – Accuracy Requirements: The desired accuracy level for the filling machine to maintain during the filling process.

By detailing these elements in the product matrix, you can ensure efficient and accurate production runs, enabling smooth operations and meeting production targets effectively.

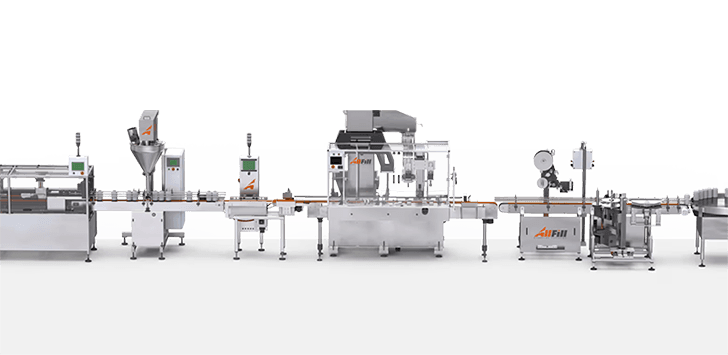

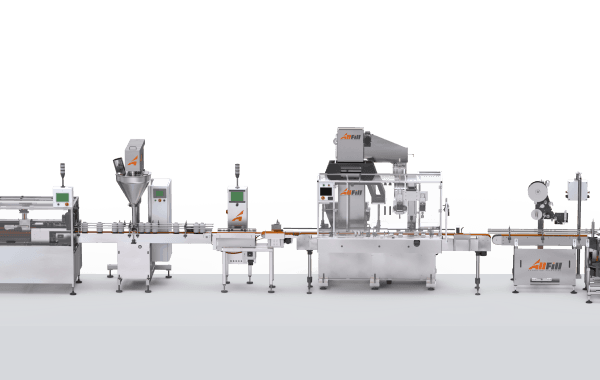

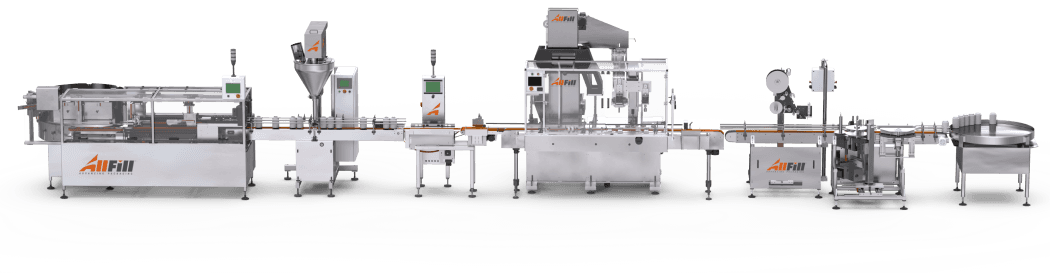

- Create a flow chart that details the different stages of production for your application. Common packaging line machinery contains product in food systems such as screw feeders, vacuum conveyors, unscrambling tables, labelers, cappers, date coders, checkweighers, vertical form fill and seal (VFFS) or bagging machines, and accumulating tables. By incorporating these stages into your flow chart, you can visualize the entire production process, identify potential bottlenecks, and ensure that each stage is accounted for in your production plan.

- Establish the utilities required for each piece of machinery and identify potential obstructions that may restrict the appropriate machinery for your application. This process ensures seamless integration of all equipment into your production line, avoiding delays and inefficiencies.

- Consider the following points to ensure your machinery meets the necessary specifications for your production process:

- Be aware of any special raw material construction requirements.

- Do you require machinery that needs to be washed down?

- Is it important to have the parts that come into contact with the product made of a special construction?

When All-Fill tests a product, we always supply the customer with a lab test report. The lab test report will contain all pertinent information relating to the tooling and the performance of the product when filled. Most importantly, the lab test clearly identifies the auger and funnel combination as well as the cycle time. The cycle time may be the most important piece of information on the lab test report. It is extremely important for OEM (original machinery manufacturers) suppliers of All-Fill auger fillers as it will determine how fast their bag machine (typically vertical form fill seal or horizontal form fill seal) will operate. Typically, a lab test is run with around 20 sample weights and the 'notes' section of the lab test really help to describe the challenges of any given product. All-Fill highly encourages customers to take advantage of the free lab test services provided. In fact, it greatly benefits All-Fill as well as the user of our machinery.

Please call 610-524-7350 or email us at info@allfill.com for more information or to schedule lab testing services immediately.

Interested in Product Testing?Need help finding the right solution?

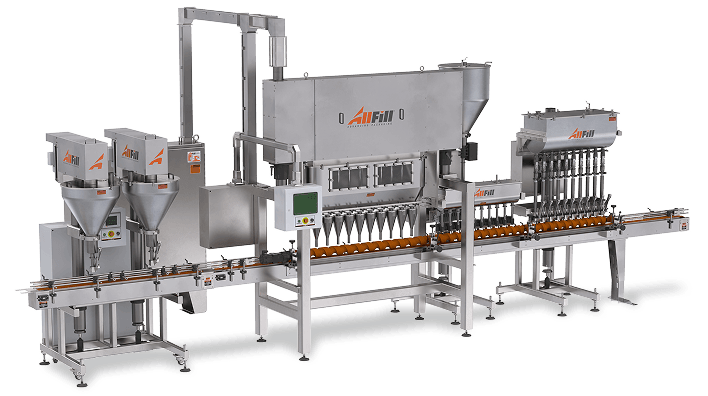

Considering Designing a Turn-Key System?

Build a System ›

Need Help?

Ask Our Experts.