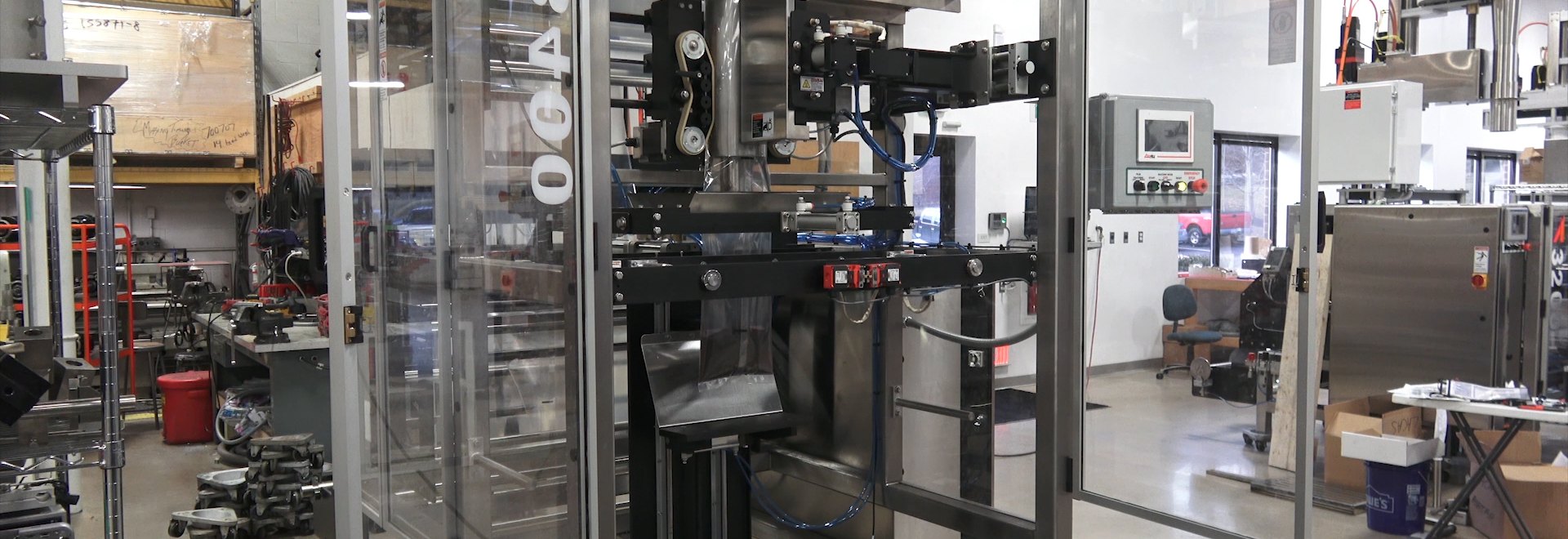

VFFS Machines & Bagging Machines

OUR PREMIER LINE OF VERTICAL FORM FILL AND SEAL BAGGERS

-

A/1200

PROVIDES ACCURATE, EFFICIENT PACKAGING OF PILLOW, GUSSETED, DOY-STYLE STANDUP BAGS AND HOLE-PUNCHES

Read More Read LessThe All-Fill A/1200 Vertical Form Fill & Seal Bagger can provide accurate, efficient packaging of pillow, gusseted, Doy-Style standup bags and hole-punches as well. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from .5 oz to 5 lb, at speeds up to 60 cycles per minute with a pneumatic jaw closure. Supported laminate film and unsupported polyethylene stocks can be easily handled with film thickness up to 0.006.” Features include 7-inch widescreen color HMI, 50 stored routines, and tool-less changeovers. The Model A/1200 is directly compatible with all filling and checkweighing equipment from All-Fill. Color touch screen controls provide easy setup, testing, and operation from self-explanatory screens and selections. Multiple recipes stored in memory can be used for each product, filling amount, or type. As with all our machines, equipment manufacturing and software programming are performed in-house for continuous, assured service, support, and assistance.

-

A/1200+

SPEEDS UP TO 100 CYCLES PER MINUTE WITH A SERVO JAW CLOSURE

Read More Read LessThe All-Fill A/1200+ Vertical Form Fill & Seal Bagger can provide accurate, efficient packaging of pillow, gusseted, Doy-Style standup bags and hole-punches as well. It is capable of forming and filling bags measuring 2.5” x 3” to 8” x 14” with volumes ranging from .5 oz to 5 lb, at speeds up to 100 cycles per minute with a servo jaw closure. Supported laminate film and unsupported polyethylene stocks can be easily handled with film thickness up to 0.006.” Features include 7-inch widescreen color HMI, 50 stored routines, and tool-less changeovers. The Model A/1200+ is directly compatible with all filling and checkweighing equipment from All-Fill. Color touch screen controls provide easy setup, testing, and operation from self-explanatory screens and selections. Multiple recipes stored in memory can be used for each product, filling amount, or type. As with all our machines, equipment manufacturing, and software programming are performed in-house for continuous, assured service, support, and assistance.

-

A/3200

FEATURES 7-INCH WIDESCREEN COLOR HMI, 50 STORED ROUTINES, AND TOOL-LESS CHANGEOVER

Read More Read LessThe All-Fill A/3200 Vertical Form Fill & Seal Bagger can provide accurate, efficient packaging of pillow, gusseted, Doy-Style standup bags, flat bottom bags and hole-punches as well. It is capable of forming and filling bags measuring 3” x 3” to 12” x 20” with volumes ranging from .5 oz to 15 lb, at speeds up to 80 cycles per minute with a servo jaw closure. Supported laminate film and unsupported polyethylene stocks can be easily handled with film thickness up to 0.006.” Features include 7-inch widescreen color HMI, 50 stored routines, and tool-less changeovers. The Model A/3200 is directly compatible with all filling and checkweighing equipment from All-Fill. Color touch screen controls provide easy setup, testing, and operation from self-explanatory screens and selections. Multiple recipes stored in memory can be used for each product, filling amount, or type. As with all our machines, equipment manufacturing, and software programming are performed in-house for continuous, assured service, support, and assistance.

-

A/3400

DIRECTLY COMPATIBLE WITH ALL FILLING AND CHECKWEIGHING EQUIPMENT FROM ALL-FILL

Read More Read LessThe All-Fill A/3400 VFFS is built to form and fill large bags sized from 12” x 14” up to 18” x 36” at speeds up to 20 cycles per minute with a pneumatic jaw closure and provides accurate, efficient packaging of pillow bags, gusseted bags, Doy-Style stand-up bags and hole-punches as well. Supported laminate film and unsupported polyethylene stocks can be easily handled with film thickness up to 0.006.” Weight capacities are as small as 5 pounds up to as much as 50 pounds. The A/3400 features color touch screen controls to provide easy setup, testing, and operation from self-explanatory screens and selections. Multiple routines stored in memory can be used for each product, filling amount, or type. The Model A/3400 is directly compatible with all filling and checkweighing equipment from All-Fill. As with all our machines, equipment manufacturing, and software programming are performed in-house for continuous, assured service, support, and assistance.

Our Bag Filling Machines

All-Fill’s Vertical Form Fill and Seal machines provide the speed and accuracy required to vertically fill and seal bags with a variety of products to help our customers meet their packaging demands. All-Fill provides a complete vertical filling solution capable of handling any product that requires laminate film structures and polyethylene films and various bag styles including gusset bags, pillow bags, doy-style stand-up bags, flat bottom bags as well as a variety of hole punches and tear notches.

Our VFFS bag filling equipment can be easily integrated with any of our filling options including auger fillers, vibratory feeders, piston fillers, volumetric cup fillers, and combination scale net weigh systems. Common bagging solutions include products such as spices and seasonings, flours, coffee, snack foods, candy, chemicals, liquids, and many others. All-Fill’s (VFFS) vertical form fill seal machines are the complete solution for flexible packaging needs.

Vertical Form Fill Seal Machine Manufacturer

By combining our 50 years of knowledge and integration experience, All-Fill has developed a series of VFFS machines. We offer four standard automatic filling and sealing machine models depending on the size of the bag and the rate of production. All-Fill Vertical Form Fill and Seal Bagging machines can seamlessly integrate with our filling, checkweighing and labeling machinery to produce packages filled with virtually any product up to 50 pounds. Our Vertical Form Fill and Seal Baggers are used in various industries and we are ready to help you decide on the right bagging machine for your business.

Benefits of working with All-Fill

-

Machines to fit your budget

Whether you are new to the packaging industry, getting ready to scale your operation or are an established packager, we have the variety of machines to fit your needs. From entry-level economy machines to high-speed lines, we engineer machines that meet your production demands and budget.

-

System Integration

In the world of packaging machinery, just about everything is custom. Our engineers are experts in customizing All-Fill equipment for maximum performance, versatility, and efficiency. We will help design, execute, and implement the perfect workflow or integrate with your existing equipment.

-

Product Experience

Auger fillers are equipped with different tooling to accommodate a variety of product characteristics. If your facility is running more than one product, you can customize a variety of tooling to make sure your equipment and product are running optimally.

-

Product Testing & Support

Every application has precise details that need to be evaluated and tested to find the perfect fit. We recommend sending sample products, bags, labels, and containers for free evaluation. As we continue to manufacture reliable equipment, we assure you we are here every step of the way.