Blog

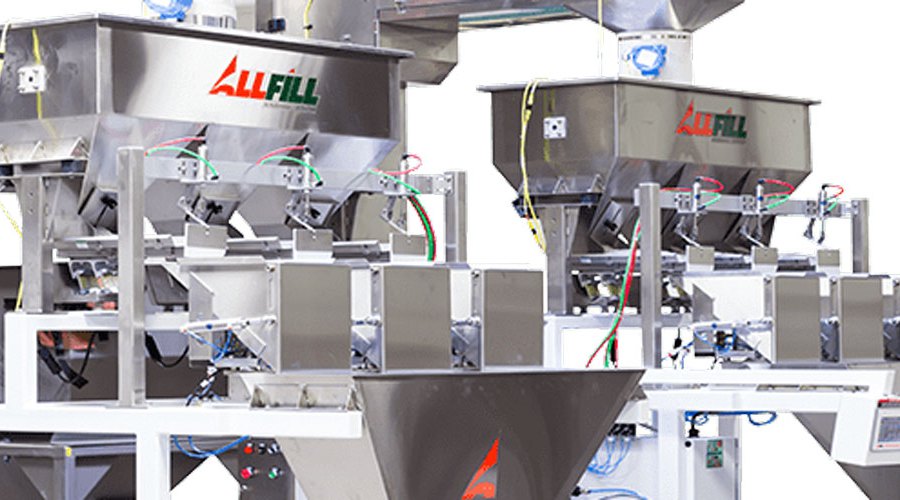

LINEAR NET WEIGHT VIBRATORY FILLERS

February 26th, 2015

Although All-Fill Inc. has become synonymous with auger filling machines, the linear net weigh vibratory fillers have come a long way since first being introduced in the late 1990’s. “All-Fill wants to handle every filling application,” states Buddy Pennisi, product line manager for All-Fill linear net weight vibratory fillers and volumetric cup fillers. “Auger fillers are often times ideal for customers whose applications need high rates of speed, but for the products that an auger filler would degrade (break down/crush/smash), a vibrator filler is ideal,” explains Pennisi.

Ideal products for linear net weight vibratory fillers are hard candies, snack foods, nuts, industrial materials like nuts and volts, rocks and uneven particulate sizes that are introduced in random consistency.

The linear net weight vibratory filler can be a very compact and easy unit to relocate in semi-automatic environments. It can also be utilized as an automatic design oftentimes integrated with a conveyor. All-Fill has worked with packaging applications using linear net weigh vibratory fillers using vibratory pans for dry goods as well as belts for products like fish pieces. The functionality of the machine is simple.

The operator creates a program for each product and each target weight that they desire to pack out. With the hopper of the machine fully loaded, a slide gate is manually adjusted so that the product can vibrate forward from the hopper to a cascading pan or directly to the weigh bucket (scale/load cell). The vibratory pan is actually on an incline although it doesn’t appear to be to the naked eye. The vibratory /cascading vibratory pan feeds the weigh bucket at various rates (frequency). The faster the rate, the harder it is to control accuracy- the slower the rate, the easier it is to control accuracy.

In a semi-automatic mode, once the weigh bucket is filled with the desired amount of product, the operator manually releases the gate on the weigh bucket to dispense the product into the container of choice. The machinery is simple to use, and it can be made custom to handle mostly any packaging challenge. All-Fill finds that many customers stretch the capabilities of the auger filler and attempt to run products on them that are more suited for vibratory fillers. When in question, consult with the All-Fill team. All-Fill offers free sample testing for potential customers and welcomes all OEM’s to inquire about our vast filling knowledge. The All-Fill sales team can be reached at 610-524-7350 or www.all-fill.com. For direct information about the linear net weight vibratory fillers and volumetric cup fillers, contact Buddy Pennisi at buddyp@all-fill.com.