High Speed Rotary Fillers

Fillers

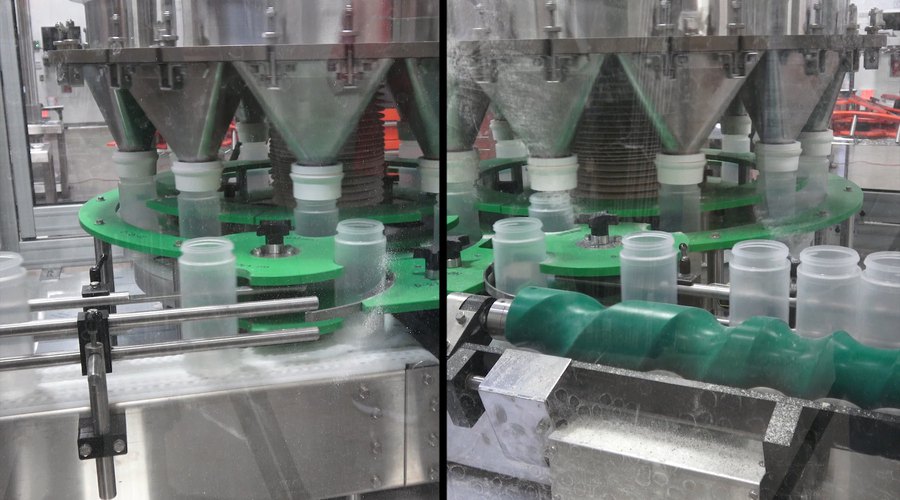

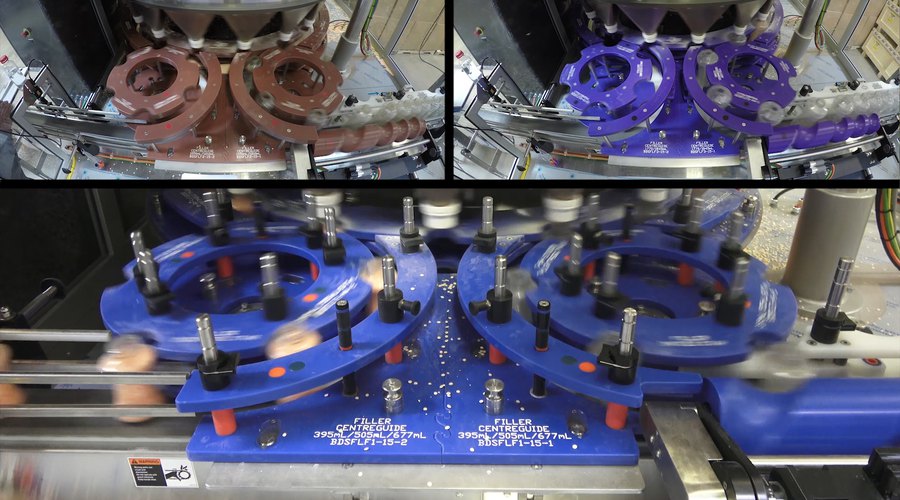

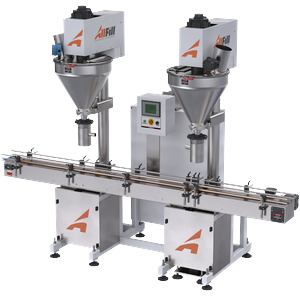

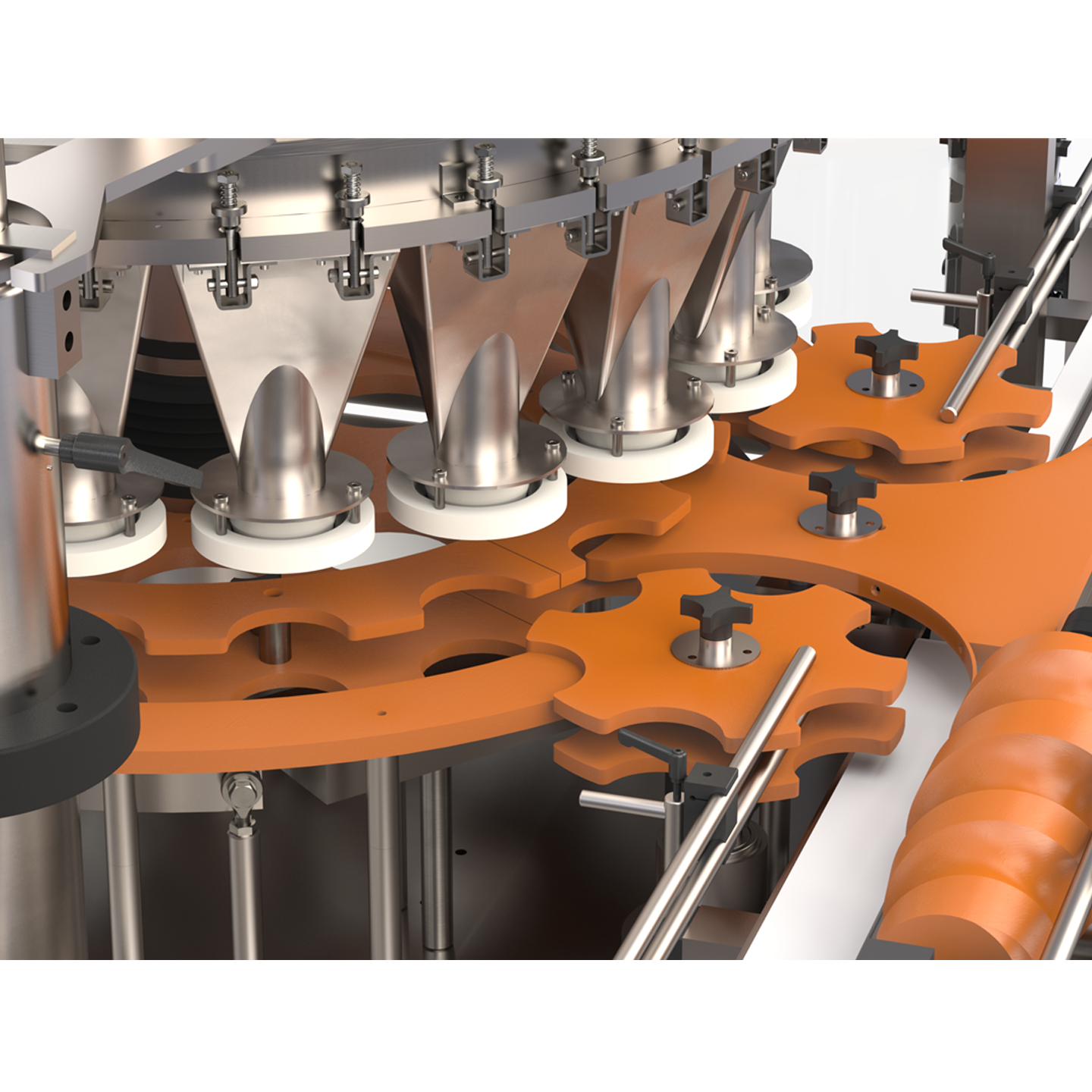

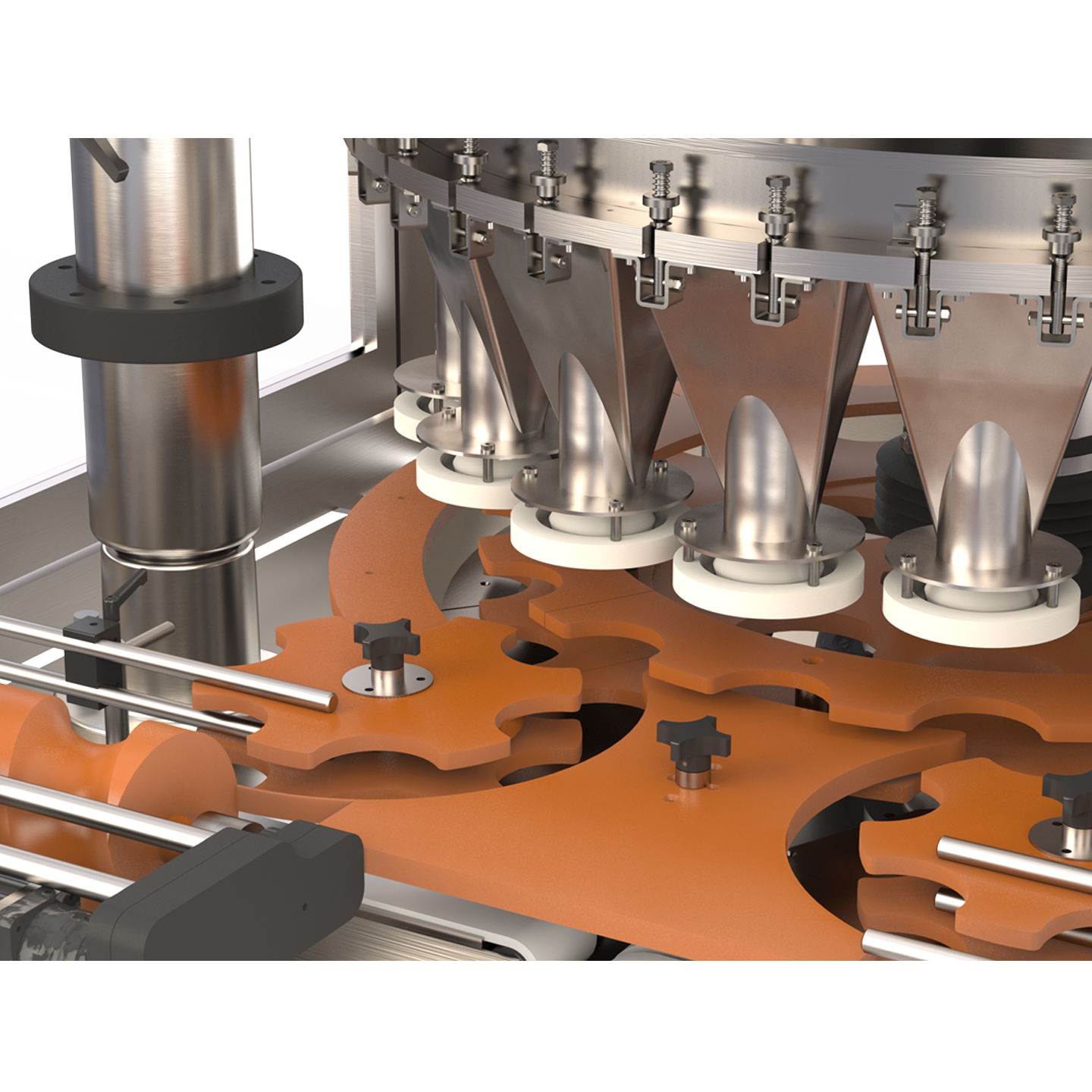

All-Fill’s line of high speed automatic rotary fillers provides high throughput and speeds for even the most demanding production environments. Rotary auger filling systems operate continuously with product dispensed into funnels traveling on a circular, multi-position turret. Containers are transported to the turret by an integral infeed conveyor. Timing screws and starwheel components space and position containers into the turret. Variable speed auger drives operate continuously to dispense product accurately. Product weight is easily adjusted by the operator or from checkweigher feedback signals, and production rates (SPM) are adjusted by varying turret speeds.

Rotary Filling Machines

Our high speed rotary auger fillers are designed to easily integrate with our other filling systems like auger, cup, and checkweighers to provide accurate and dependable filling consistently. We can accommodate a huge selection of dry products into containers of many sizes. These high speed filling machines are available to a variety of industries like pharmaceutical, nutraceutical, cosmetics, industrial and agricultural chemicals, pet products, powders, granules, and foods to fill rigid containers quickly and efficiently.

Specifications

-

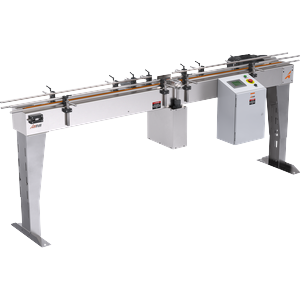

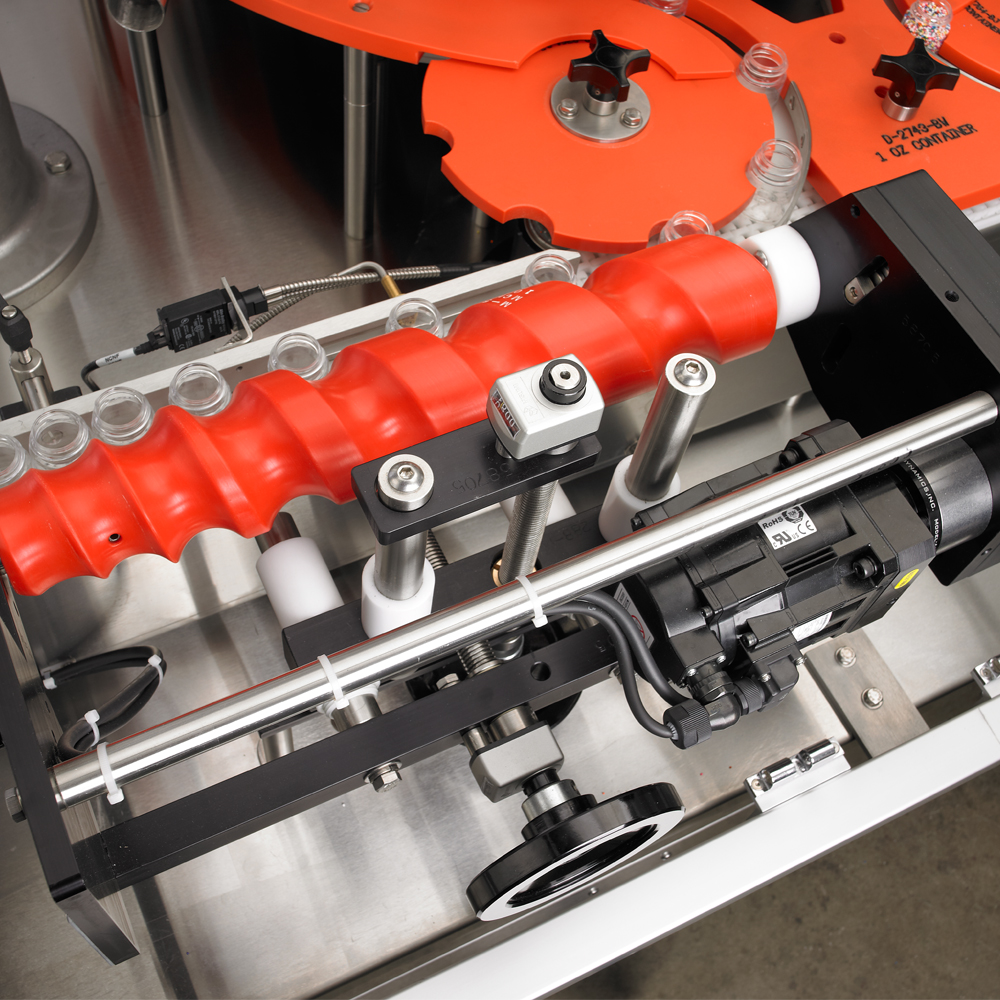

ConveyorStainless steel (Type 304) conveyor channel with acetyl flat top chain and variable speed DC drive motor with reducing gearbox. Chain sprocketing and drive components.

-

BaseFully enclosed, stainless steel, clad steel base cabinet with removable access doors, stainless steel top, and mechanical jack to raise/lower fill head.

-

FeaturesFully enclosed, stainless steel base with removable access doors, Single or dual head filling capacity or more, depending on application timing screw and starwheel components for spacing and positioning of the containers

-

Container HandlingSystems include one complete set of container handling parts supplied, including: lnfeed & outfeed starwheels. Removable main starwheel segments. Outer guide rails. Timing screw & adapter. lnfeed guide rails. Intermediate guide.

-

Filling Positions / Pockets12-60 position fixed turret assembly divider plate and funnel carriage

-

Operating CyclesUp to 400+ a minute dependent on number of pockets and fill size

-

Contact PartsStandard 304 stainless steel. Optional 316 stainless steel

-

OptionsContainer and product vibration. Missing container detection. Hopper agitation. Level Control. Motorized Column jack. Compartmented hoppers for varied products. Weight feedback. Variable hopper agitation speed selection. Clear hopper viewport for product inspection and tooling adjustment.

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Fertilizer Pellets

-

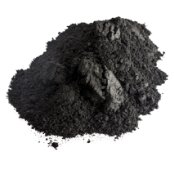

Toner Powder

-

Cat Litter

-

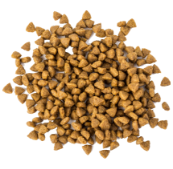

Small Pet Food

-

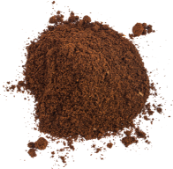

Whole & Ground Coffee

-

Sugar

-

Jimmies & Sprinkles

-

Plant Foods

-

Food Powders

-

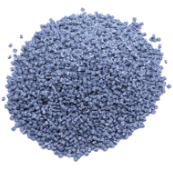

Plastic Granules

-

Ground Spices

-

Flake Spices

-

Fine Cut Tobacco

-

Flour Powder

-

Whole & Ground Pepper

-

Detergent Powder

-

Infant Formula

-

Cake Mix

-

Pancake Mix

-

Cement Powder

-

Cocoa Powder

-

Matcha Powder

-

Cosmetic Powder

-

Curry Powder

-

Protein Powders

-

Turmeric Powder

-

Parsley & Oregano

-

Grains

-

Seeds

-

Chia Seeds

-

Grass & Fennel Seeds

-

Salt Products

-

Rice Products

-

Lentils

-

Breadcrumb

-

Brown Sugar