Checkweigher Machines

OUR PREMIER LINE OF CHECKWEIGHERS

-

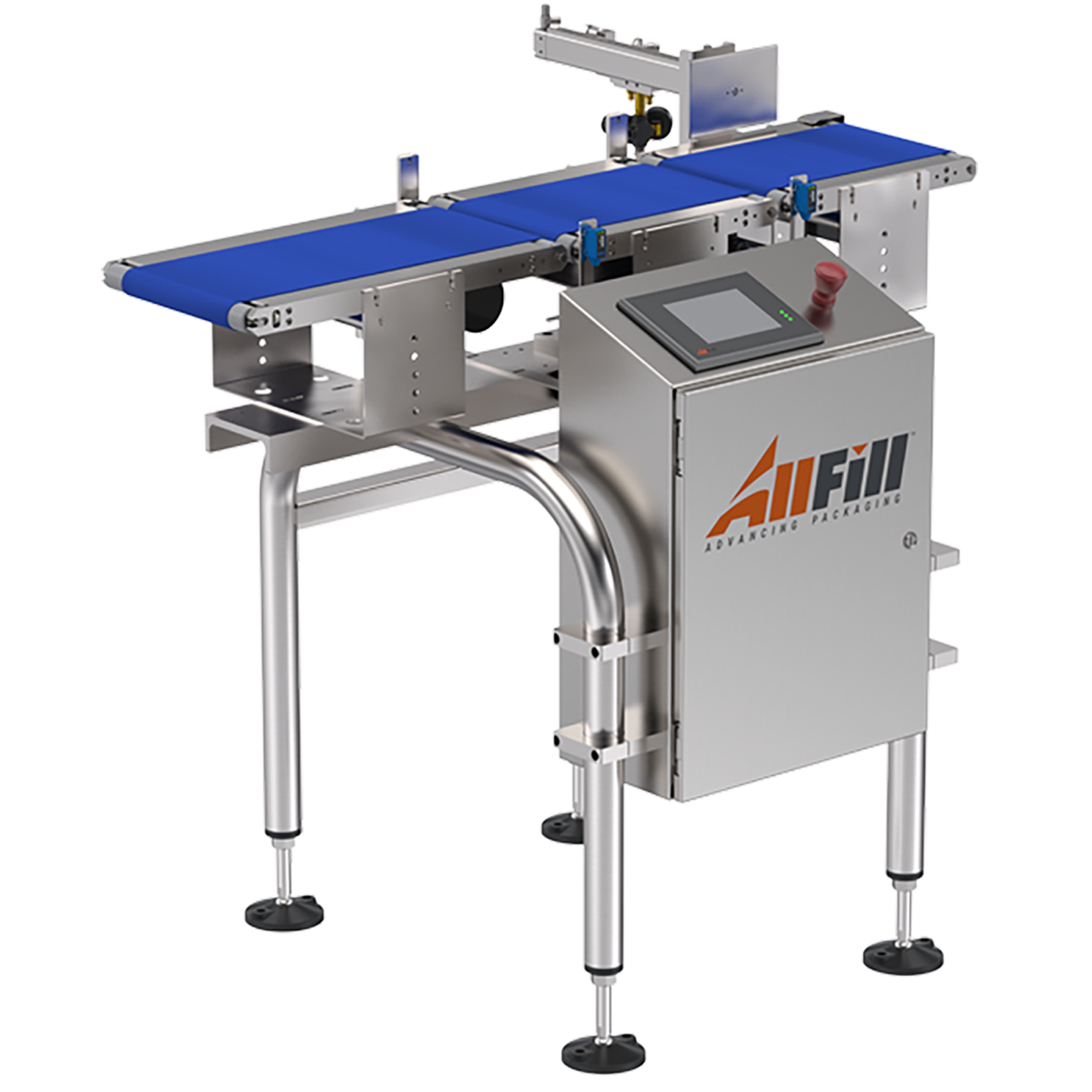

EW/8

OUR MOST COMMON CHECKWEIGHER

Read More Read LessModel EW/8 is All-Fill’s economical solution for users and applications that may only require an entry level checkweigher. The EW/8 offers 0.5g resolution. Utilizing a strain gauge load cell for weighing packages up to 5 lbs and operating at speeds of up to 120 packages per minute, makes the EW/8 just as versatile and reliable as other All-Fill models.

-

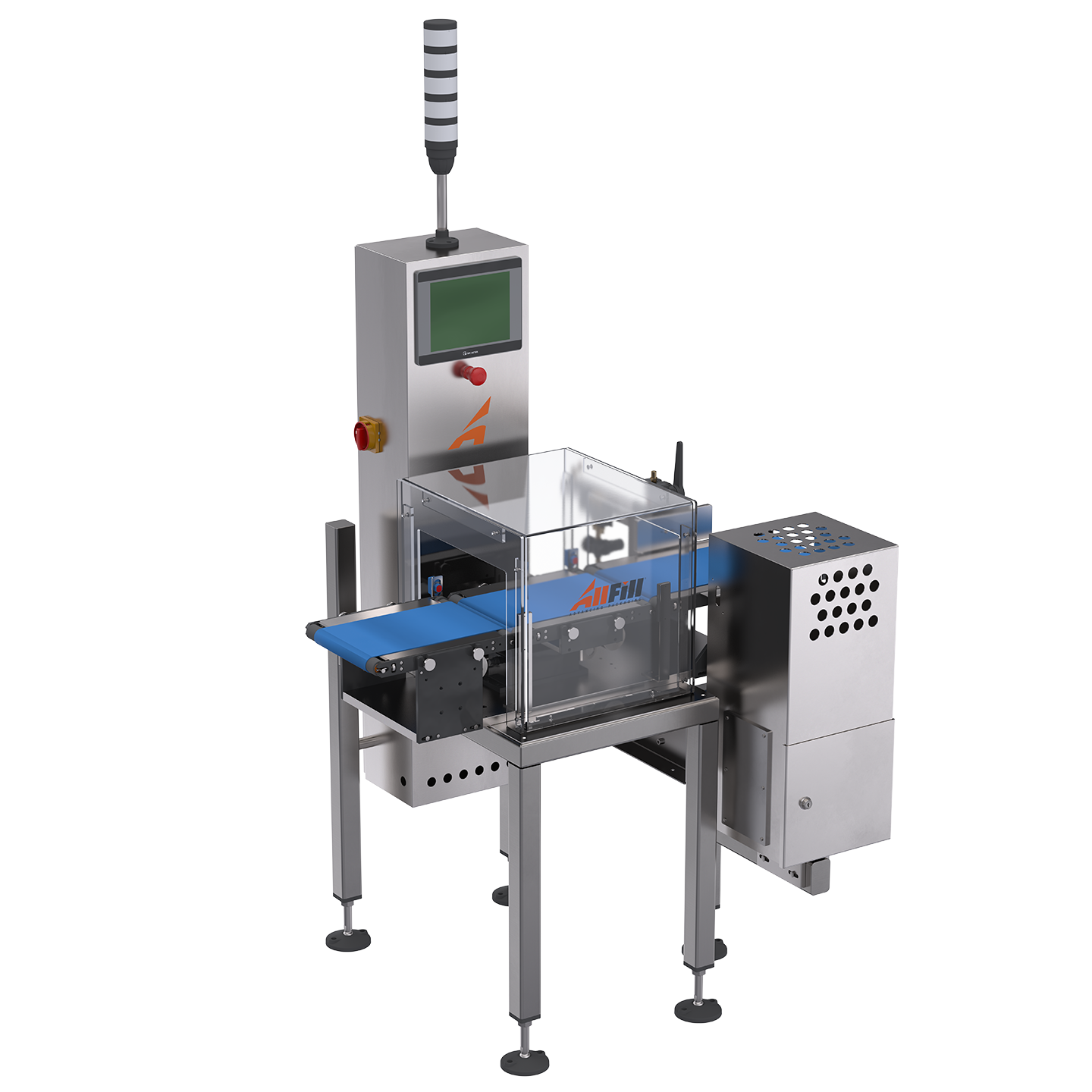

HP/14

THE STRATEGIC PACKAGING SOLUTION TO AVOID PRODUCT WASTE AND INCREASE EFFICIENCES

Read More Read LessThe High Precision checkweigher is capable of handling packages up to 8 lbs at a speed of 300 containers per minute. Due to use of an electromagnetic force restoration load cell, that comes standard with the HP/14, some applications can achieve accuracies of ± 100mg. Easily integrated with any filler, bagger, and metal detector, an All-Fill Checkweigher is the strategic packaging solution to avoid product waste and increase efficiencies.

-

CW/10

THE CHECKWEIGHER FOR FAST AND ACCURATE WEIGHING APPLICATIONS

Read More Read LessWeighing packages up to 10 lbs at speeds of 250 containers per minute, All-Fill’s CW/10 is the checkweigher for fast and accurate weighing applications. Our modular design offers the ruggedness and durability for demanding production environments. The CW/10 can achieve accuracies to 0.5 grams, depending on the application. Save money and maximize efficiencies with our seamless filler integration and feedback capabilities.

-

PW/12

CHECKWEIGHING SOLUTION FOR FLEXIBLE AND RIGID CONTAINERS

Read More Read LessAll-Fill’s model PW/12 power weigh table is the reliable and accurate checkweighing solution for flexible and rigid containers and packages up to 8 lbs. Operating at speeds of up to 250 packages per minute, the PW/12 can accurately weigh ± 0.5g depending on the application. The PW/12 features a precision digital load cell and is the most popular unit due to its versatility.

-

MW/16

ACCURATE WEIGHT CONTROL OF CASES, BULK BAGGED PRODUCTS, CORRUGATED BOXES, ETC.

Read More Read LessFor fast and accurate weight control of cases, bulk bagged products, corrugated boxes or other medium weight items up to 35 lbs., trust All-Fill’s model MW/16 to get the job done. Consisting of a versatile digital strain gauge load cell, the MW/16 can operate at speeds of 70 packages per minute with an accuracy of ± 2 grams depending on application.

-

HW/15

INCREASE ACCURATE PRODUCTION WITH THIS HEAVYWEIGHT CHECKWEIGHER

Read More Read LessAll-Fill’s heavyweight checkweigher is ideal for handling up to 200 lbs. of weight and operating at speeds of 50 packages per minute. Featuring 4 load cells, the HW/15 can weigh with an accuracy of ± 0.25 oz depending on the application. Reduce waste and increase accurate production with a heavyweight checkweigher from All-Fill.

Our Checkweigher Machines

All-Fill Checkweighers, formerly Alpha Checkweighers, specializes in the design and manufacturing of a comprehensive range of checkweigher solutions including automatic checkweighers, hi-speed checkweighers, inline checkweighers, and conveyor belt scales. Checkweigher systems are ideal for companies looking to reduce waste, save money, and increase their production line’s efficiency. All-Fill checkweigher machines are extremely versatile and can be adapted to handle virtually every package, bag, carton, box, and bottle.

Standard checkweigher models are available for the quickest deliveries in the industry. We can also design and manufacture custom check weighing equipment to meet your unique product demands. Integration of the checkweigher system with OEM metal detectors is common and highly encouraged when constructing production lines where quality and safety are a necessity.

A Trusted Checkweigher Manufacturer

As renowned checkweigher manufacturers, All-Fill prides themselves on the versatility of their equipment. Our checkweighers are designed to make sure your product is coming off the conveyor scale within a certain speed and maintaining an accurate weight for your desired product. If you are not sure which checkweigher system will fulfill your weighing needs, we will help you decide.

Benefits of working with All-Fill

-

Machines to fit your budget

Whether you are new to the packaging industry, getting ready to scale your operation or are an established packager, we have the variety of machines to fit your needs. From entry-level economy machines to high-speed lines, we engineer machines that meet your production demands and budget.

-

System Integration

In the world of packaging machinery, just about everything is custom. Our engineers are experts in customizing All-Fill equipment for maximum performance, versatility, and efficiency. We will help design, execute, and implement the perfect workflow or integrate with your existing equipment.

-

Product Experience

Auger fillers are equipped with different tooling to accommodate a variety of product characteristics. If your facility is running more than one product, you can customize a variety of tooling to make sure your equipment and product are running optimally.

-

Product Testing & Support

Every application has precise details that need to be evaluated and tested to find the perfect fit. We recommend sending sample products, bags, labels, and containers for free evaluation. As we continue to manufacture reliable equipment, we assure you we are here every step of the way.