Automatic Auger Filling Machines

OUR PREMIER LINE OF AUTOMATIC AUGER FILLERS

-

MODEL SHA

PRECISION SELECTION AND ADJUSTMENT OF FILL AMOUNTS

Read More Read LessAll-Fill’s Model SHA automatic single head auger filler is a complete, economical solution to your filling production line requirements. It consists of the industry-proven All-Fill filling head, an independently motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.). PLC control system provides precise selection and adjustment of fill amounts and machine functioning.

-

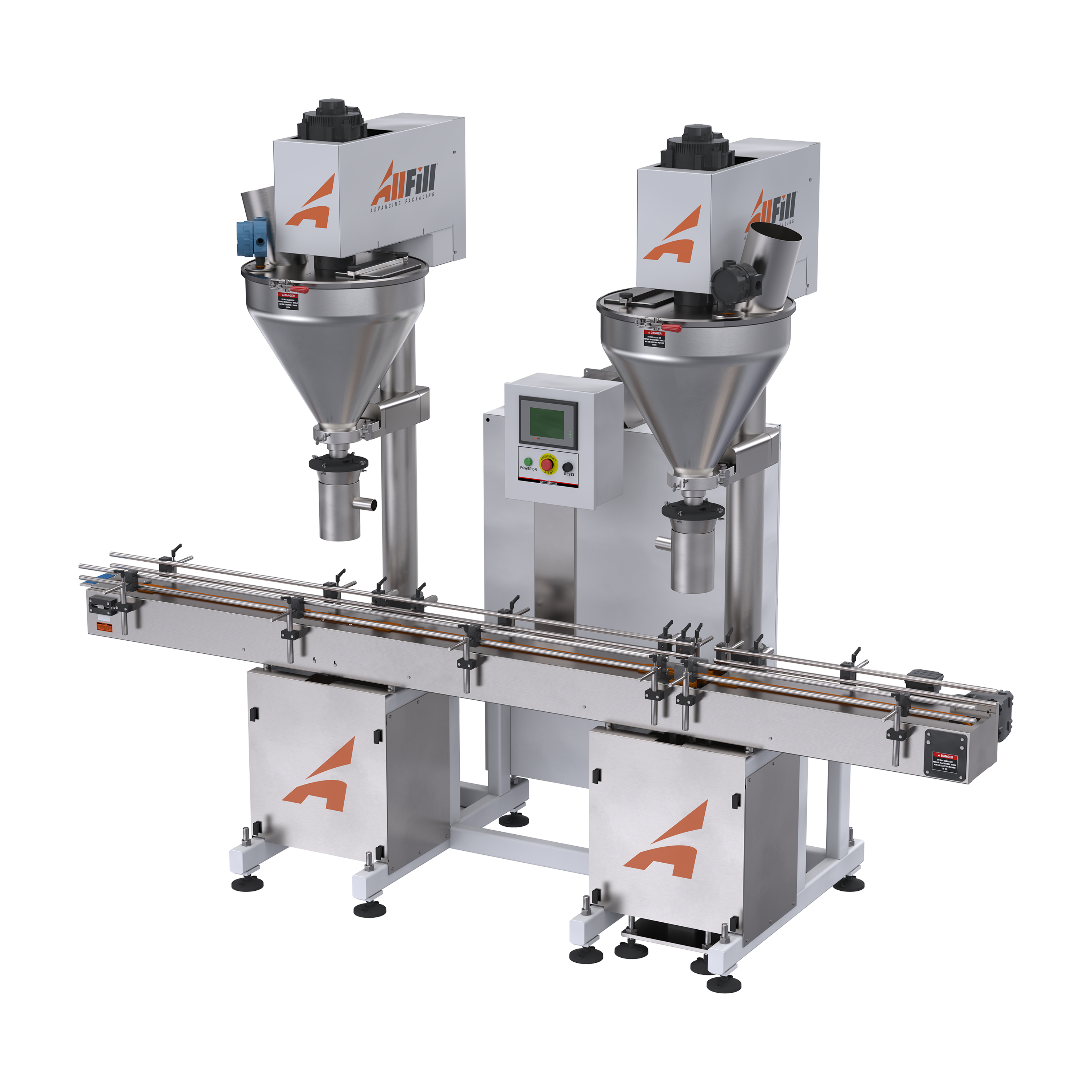

MODEL DHA

COMPLETE ECONOMICAL SOLUTION FOR YOUR FILLING NEEDS

Read More Read LessAll-Fill’s Model DHA automatic auger filler is a complete, economical solution to your filling production requirements. It consists of the industry-proven All-Fill filling heads, conveyor mounted on a sturdy frame, and container indexing controls that reliably move and position for filling. This auger filler also includes an Allen Bradley PLC control system with a touchscreen that provides precise selection and adjustment of fill amounts and machine functioning. Provides easy setup, operation, and monitoring of the filling operation.

-

MODEL TAA

DESIGNED FOR HIGH SPEED AND HIGH VOLUME

Read More Read LessAll-Fill’s Model TAA automatic auger fillers are designed for high speed and high volume, dispensing typically encountered in vertical form-fill-seal, cup filling, or other applications requiring dual-position filling. Each unit is designed exactly to your requirements. Our filling application specifies each Model TAA auger filler. The center distance between the 2 augers can range from as little as 2″ to well over 6″. Forming tube diameter, funnel length, and height will match your specific equipment. Tooling and accessories, such as augers, collector funnels, cutoffs, etc., are supplied to best suit your product, production rates, and accuracy levels.

Our Automatic Filling Machines

All-Fill’s completely automatic auger filling machines are the solution to your demanding filling requirements. Our machines consist of industry-proven All-Fill filling heads, conveyors mounted on a sturdy frame, and container indexing controls that reliably move and position for filling. All-Fill's automatic auger fillers are designed for complete, continuous container transport, positioning, filling, and discharge to the next stage in the packaging process. An indexing system mounted on the conveyor regulates container movement toward the filling position, centers each container for filling, then moves the container away.

Available in single or multiple head configurations, automatic auger filler models can be equipped with a variety of accessories and options to suit particular container handling or product characteristics. A custom programmable logic controller with a touchscreen provides precise selection and adjustment of fill amounts and machine functioning: providing easy setup, operation, and monitoring of the filling operation.

What Automatic Auger Filling Machines Can Do For Businesses

The All-Fill Auger Filler is the foundation of the product line. Always reliable and built to last, All-Fill’s auger filling machines are the pinnacle of the industry. Automatic auger fillers are designed for complete, continuous container transport, positioning, filling, and discharge to the next stage in the packaging process. All-Fill’s completely automatic auger filling machines are the solution to your demanding filing requirements.

Using a variety of standard to custom auger tooling/accessories, All-Fill automatic auger fillers can easily handle a wide range of products such as powders, detergents, household chemicals, cosmetics, and seasonings and spices. If you are not sure which automatic filler is right for you, we will help you decide.

We’re easy to talk to for all inquiries, questions, or comments. Complete this simple form below to request further information tailored to your needs.