MAKING THE CEREBUS WITH MR. HA DINH

1985-1987

ALL COMPANIES HAVE A GREAT SUCCESS STORY; ALLOW US TO PROUDLY SHARE OURS. ALL-FILL INC. IS A FAMILY OWNED AND OPERATED THAT HAS THRIVED OVER THE COURSE OF THREE GENERATIONS OF EDGINTON’S.

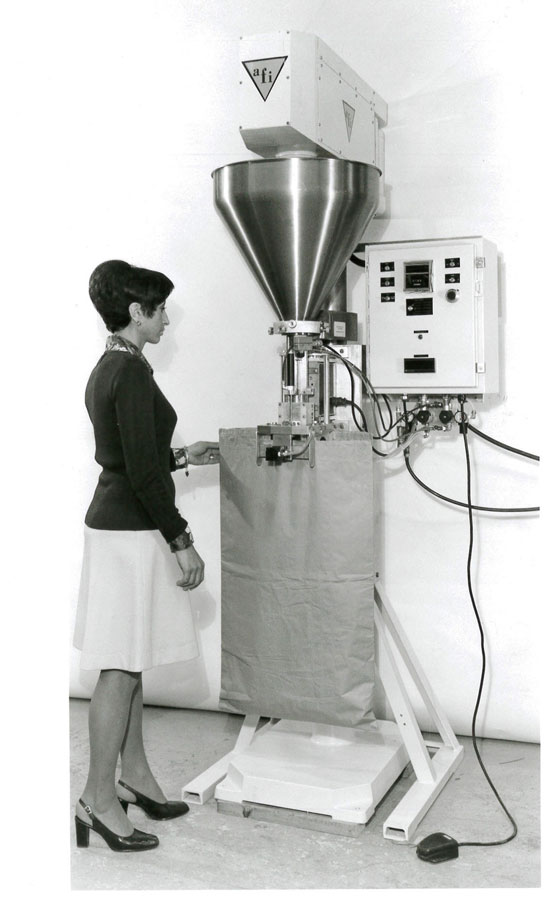

Since the very beginning of 1969 some employees have come and gone, others are still employed to this day. The industry has changed and All-Fill was eager to adapt along the way. There were tough times, there were always great times. No matter the business, the key to success is hard work and determination. Never was this truer than in the very beginning, the early years in which the first employees laid the structural foundation and required a work ethic for long-term success and growth. At All-Fill, we have a great story to tell, enjoy following the history of our company throughout this blog series and we will get back to work so that we can continue writing future chapters.

1985:

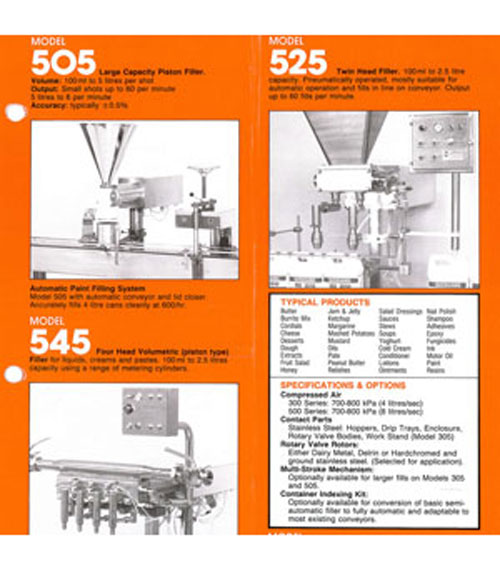

IN THE MID 1980’S, ALL-FILL WAS ACTUALLY PART OF AN ORGANIZATION CALLED THE ALL-FILL GROUP. THE ALL-FILL GROUP CONSISTED OF ALL-FILL INC., ALL CONTROL SYSTEMS (ACS) AND AUGER MANUFACTURING (AMS). ALL-FILL INC. AND ACS SHARED A FACILITY TO WORK OUT OF IN THE GREAT VALLEY CORPORATE CENTER. TOGETHER, THE ALL-FILL GROUP HAD A SLOGAN, “FOR PACKAGING PROCESSES WITH A FUTURE… FROM CONCEPT TO INSTALLATION.”

The All-Fill group ultimately did not last more than a few years as AMS ultimately branched off because of the establishment of Auger Fabrication and ACS was sold. When ACS related to All-Fill though, All-Fill was able to utilize ACS expertise in PLC implementation to provide the control system required for custom and sophisticated filling applications. However, at that time the PLC system cost was very high, so it was limited only to the high-end filling applications.

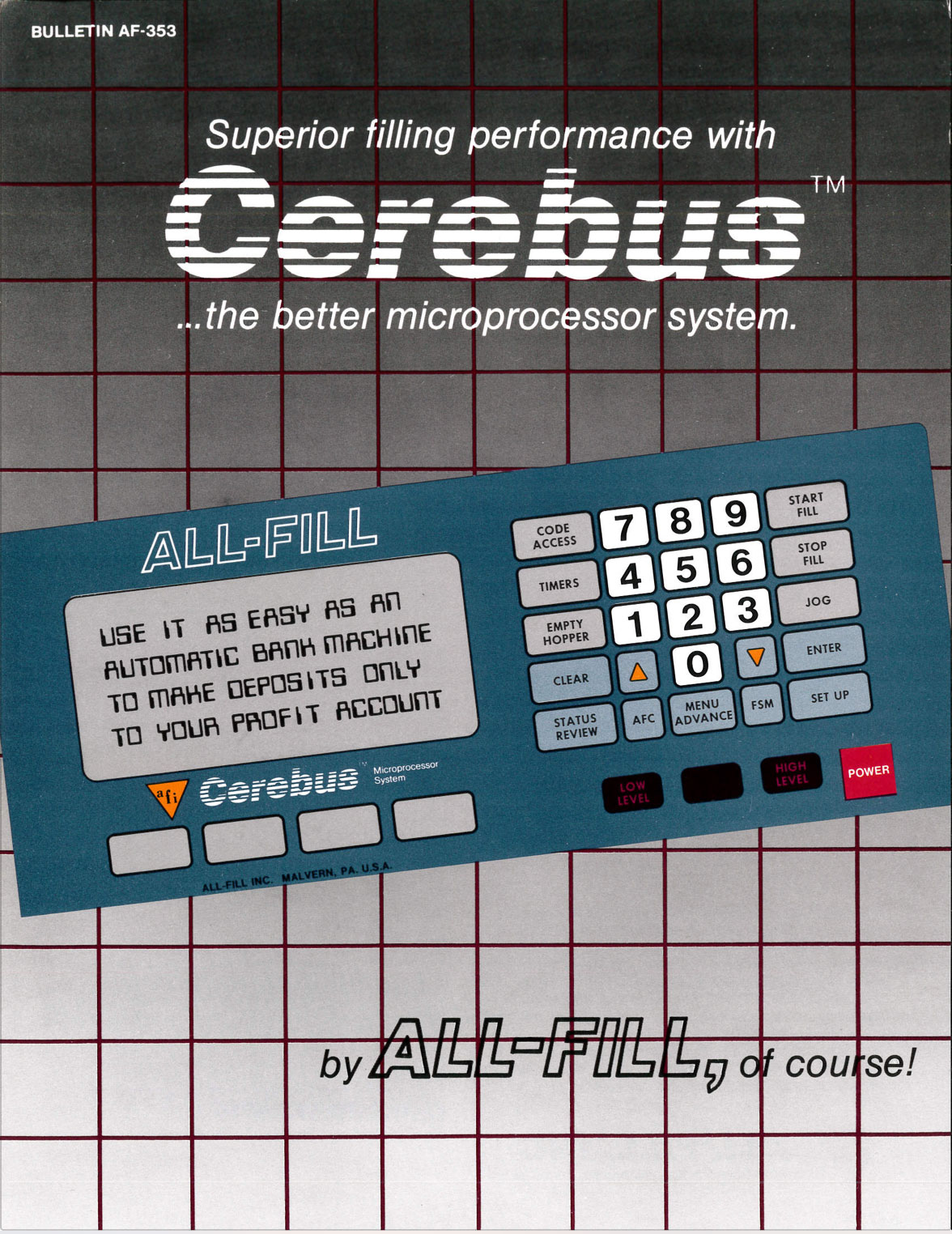

Mateer was still an industry leader for auger filling, and they had a proprietary control called Neotron. ACS was asked to come up with computer control to compete with the Neotron. ACS wanted a control that was also expandable and cost effective. Ha Dinh was an electrical engineer with the previous background in machine and factory control automation from the hi-tech semiconductor assembly equipment industry and he joined ACS to develop this computer control which was tailored to the packaging machinery. This control was specified to have capabilities to control all the operation of filling machine from simple Model B’s to sophisticated multiple fillers, scales, associate packaging devices, and integration with other equipment via I/O or data communication.

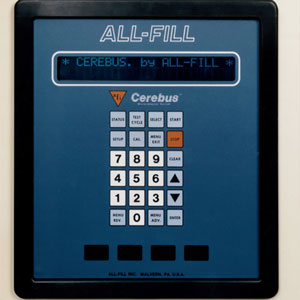

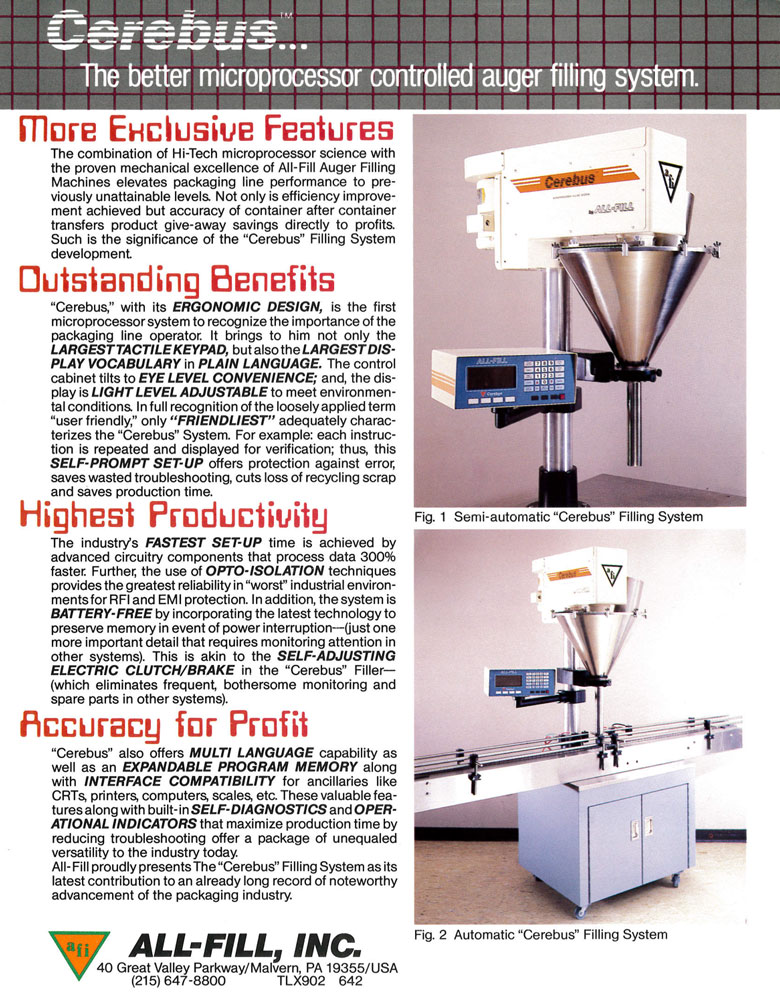

After 6 months of design, prototype, testing and developing software by Ha Dinh, the 1st generation of All-Fill computer control was successfully incorporated in the auger filling application. This control system was named Cerebus II, and the computer board was named HaDinh 100.

THE AUGER FILLER WITH THE CEREBUS CONTROL WAS EQUIPPED WITH MANY NEW FEATURES SUCH AS MULTIPLE RECIPES, PROGRAMMABLE TIMERS, AUGER REVOLUTIONS, AGITATION MODE, PRODUCT RECIPES, AUTO WEIGHT CORRECTION VIA OFF-LINE ELECTRONIC SCALE AND MANY MORE.

The Cerebus was introduced at the PMMI show in 1986 in the Javits Convention Center in New York City. This control was well received by the customers. During the show the electrical power to the convention was overloaded and the voltage dropped below the acceptable level which caused a lot of control components to behave abnormally. However, the Cerebus II control system still worked flawlessly during this time.

AS MANY NEW APPLICATIONS AROSE, NEW FEATURES WERE REQUIRED TO MEET THE FILLING NEEDS. THE CAPABILITY OF CEREBUS II WAS OBVIOUS AND IT WAS PROVEN TO MEET THE DEMANDING TASKS OF LOW COST AND CHALLENGING APPLICATIONS.

Many filling modes were incorporated in the control- Fill by revolution – By scale- set point or bulk and dribble- Multiple augers and scales were integrated together to meet the accuracy and speed requirements. As an example, in 1986, an original Cerebus II control filling system could fill, weigh, and mix up to 4 different products using 4 independent augers and 5 scales to control the filling and weighing operation of the filling line to meet required accuracy of .25% and line speed. This system is still working today at an Ohio Pharmaceutical facility.

BASED UPON THE SUCCESSFUL INSTALLATIONS INVOLVING FILL BY WEIGHT, ALL-FILL WAS ABLE TO USE THE CERBUS II TO CONTROL THE ORIGINAL ALPHA CHECKWEIGHER (ALTHOUGH NOT ALPHA AT THE TIME!), IT WAS CALLED GURADIAN.

The Cerebus was introduced at the PMMI show in 1986 in Javits Convention Center in New York City. This control was well received by the customers. During the show the electrical power to the convention was overloaded and the voltage dropped below the acceptable level which caused a lot of control components to behave abnormally. However, the Cerebus II control system still worked flawlessly during this time.