A MORE "FLUID" APPROACH

1988

ALL COMPANIES HAVE A GREAT SUCCESS STORY; ALLOW US TO PROUDLY SHARE OURS. ALL-FILL INC. IS A FAMILY OWNED AND OPERATED THAT HAS THRIVED OVER THE COURSE OF THREE GENERATIONS OF EDGINTON’S.

Since the very beginning of 1969 some employees have come and gone, others are still employed to this day. The industry has changed and All-Fill was eager to adapt along the way. There were tough times, there were always great times. No matter the business, the key to success is hard work and determination. Never was this truer than in the very beginning, the early years in which the first employees laid the structural foundation and required a work ethic for long-term success and growth. At All-Fill, we have a great story to tell, enjoy following the history of our company throughout this blog series and we will get back to work so that we can continue writing future chapters.

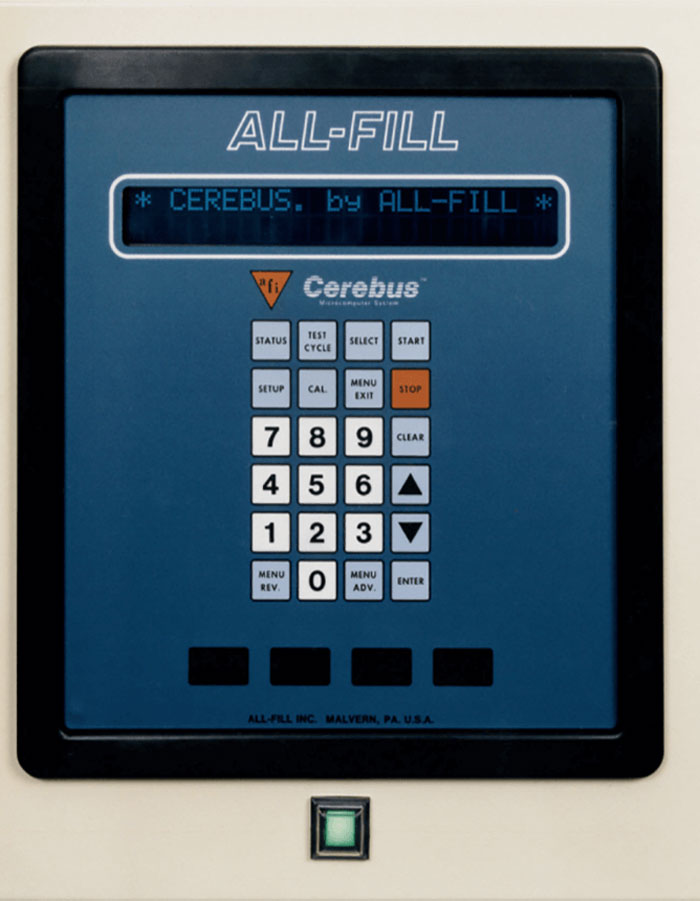

BY THE END OF THE 1980’S, ALL-FILL WAS CHARGING HARD INTO THE 1990’S, AN ERA WHERE TECHNOLOGY AND THE INTRODUCTION TO THE FIRST COMPUTERS USED WITHIN THE BUILDING WOULD BEGIN TO REVOLUTIONIZE THE PACKAGING INDUSTRY.

All-Fill was firmly entrenched into the auger filler and cup filler markets and was an emerging threat with the new line of checkweighers. Auger filler sales to OEM partners, specifically manufacturers of VFFS (vertical form fill seal) machinery were never better. While attending trade shows, prospective customers would often bring their dry packaging application to All-Fill and then mention that they also had a liquid filling application as well. All-Fill’s answer was simple… if it couldn’t be metered with liquid tooling, we don’t have a solution. Typically, that inquiry was turned over to a manufacturing specialist from the liquid industry, but it always felt like a missed opportunity for All-Fill to capture. “It was frustrating!” said Richard Edginton exclaimed. “So many liquid filling projects would be presented to us, and we didn’t really have a great answer. Granted, we had to draw the line somewhere and not all liquid applications are best suited for a dry filling company, but we did want to help the people with relatively simple liquid projects. After all, we are All-Fill!”

IN 1963 JOHN HUNTER ESTABLISHED A COMPANY IN NEW ZEALAND, TAKING ADVANTAGE OF HIS ENGINEERING BACKGROUND TO FULFILL HIS LIFELONG GOAL OF BECOMING HIS OWN BOSS.

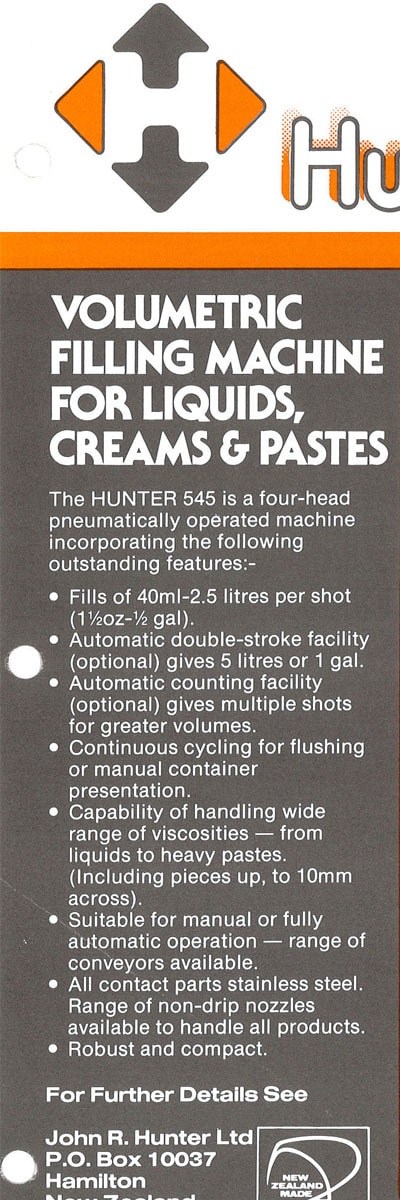

As with most small start-ups, John Hunter started the business out of his family’s garage and moved to a new facility within a year of inception. The company’s primary business, however, had nothing to do with packaging machinery, they produced office furniture! The new factory was shared with two other businesses, one of which was a manufacturer of a hydraulic engine hoist. The hydraulic engine hoist company had a contract at the time to manufacture filling machines for Plastics Products Ltd. A very progressive company at the time, Plastic Products Ltd. was interested in volumetrically filling the bottles that they were producing. All-Fill in the USA was proof that volumetric filling, being that of the dry or liquid variety was nothing new, but in New Zealand there were no major players, a niche market developed for John Hunter.

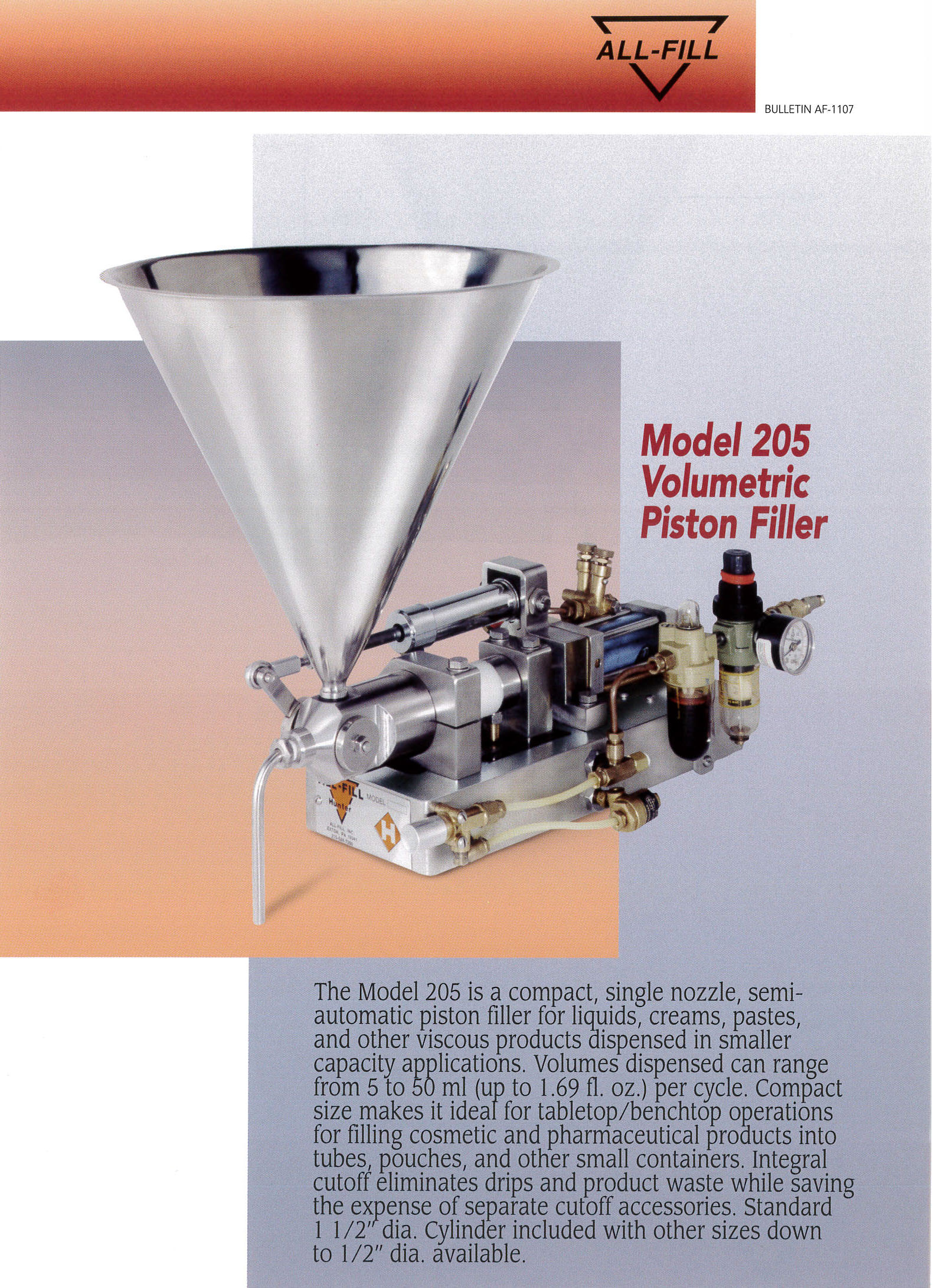

When John Hunter and All-Fill began discussions in the late 1980’s it was a perfect fit. All-Fill was eager to offer a private labeled machine to complement its diverse range of powder fillers and John Hunter was looking for stability and slow growth for his start up business. All-Fill began to display the Hunter piston filler at trade shows and promoting the product line through its own literature. The model 305 piston filler was the staple of All-Fill’s offering. The model 305 was a semi-automatic piston filler that was fully pneumatically operated, no power was required. In the simplest terms, a hopper containing liquid would be situated above the core of the piston filler. Below the hopper was a cylinder set with a piston inside. As the piston drew back, a limit switch would indicate the stop position and the piston would push forward to deliver a volumetric fill out of a given nozzle (determined by application). The principle was simple and like the operation of All-Fill auger fillers, the same principle was duplicated across the product line, the machines just grew in size, shape and scope.

TO THIS DAY, ALL-FILL BASICALLY STILL SELLS THE SAME HUNTER PRODUCT LINE; IT HAS REMAINED A GREAT PARTNERSHIP THROUGH THE YEARS WITH TO DATE SALES OF OVER 550 UNITS.

John Hunter has been officially retired since 1986 and his son Frank Hunter assumed control of the company until 2007. Many of All-Fill’s recent dealings have been with Niall Fuller, the current Managing Director of Hunter Filling Systems. Niall, a mechanical engineer by trade, has really elevated the status of Hunter as they have recently expanded into a brand new, state of the art production facility that increased their working space by 4 times. Niall and the rest of the Hunter team continue to provide All-Fill with a diverse product line featuring many semi-automatic and automatic models to handle virtually every slow to moderate speed liquid packaging application. As of 2013, Hunter is now serving as a distributor of All-Fill semi-automatic auger filling machines as well.

All-Fill carries a vast majority of Hunter parts in house for quick delivery of new machine orders as well as replacement or spare parts. The Hunter filling line has become synonymous with All-Fill, and the partnership is built to last for many years to come.