Labeling Machines

OUR PREMIER LINE OF LABELERS

-

WRAP SERIES

APPLIES LABELS TO RIGID AND ROUND CONTAINERS, AND SQUARE BOTTLES WITH ROUNDED EDGES

Read More Read LessThe Wrap Series of Labelers is designed to apply pressure sensitive labels to rigid and round containers, and square bottles with rounded edges. All-Fill labeling equipment has a variety of options including semi-automatic and automatic machines, featuring touch panel controls for quick and easy changeovers. There are also economical Wrap Labelers that are designed for limited volume production lines or start-up operations. We reduce the need for change parts with an open frame design that features a fully adjustable and versatile machine. All of our Wrap Labeling Systems are designed with ease of operation in mind. All adjustments to the label and label placement can be made on the fly, without interrupting the machine's operation. Label changeover and minor adjustments may be made without the use of tools.

-

PANEL SERIES

FEATURES TOUCH PANEL CONTROLS FOR QUICK AND EASY CHANGEOVERS

Read More Read LessThe Panel Series of labelers is designed to apply pressure sensitive labels to rigid containers with single or multiple panels. All-Fill labeling equipment has a variety of options including semi-automatic and automatic machines, featuring touch panel controls for quick and easy changeovers. There are also economical Panel Labelers that are designed for limited volume production lines or start-up operations. We reduce the need for change parts with an open frame design that features a fully adjustable and versatile machine. All of our Panel Labeling Systems are designed with ease of operation in mind. All adjustments to the label and label placement can be made on the fly, without interrupting the machine's operation. Label changeover and minor adjustments may be made without the use of tools.

-

TOP & BOTTOM SERIES

ALL ADJUSTMENTS TO LABELER CAN BE MADE ON THE FLY

Read More Read LessThe Top/Bottom Labeler is a system designed to apply pressure sensitive labels to the top and/or bottom panels of flexible or rigid products or containers. A height adjustable post allows it to label products from empty bags to full boxes. All-Fill labeling equipment has a variety of options including semi-automatic and automatic machines, featuring touch panel controls for quick and easy changeovers. There are also economical Top/Bottom Labelers that are designed for limited volume production lines or start-up operations. We reduce the need for change parts with an open frame design that features a fully adjustable and versatile machine. All of our Top & Bottom Labeling Systems are designed with ease of operation in mind. All adjustments to the label and label placement can be made on the fly, without interrupting the machine's operation. Label changeover and minor adjustments may be made without the use of tools.

-

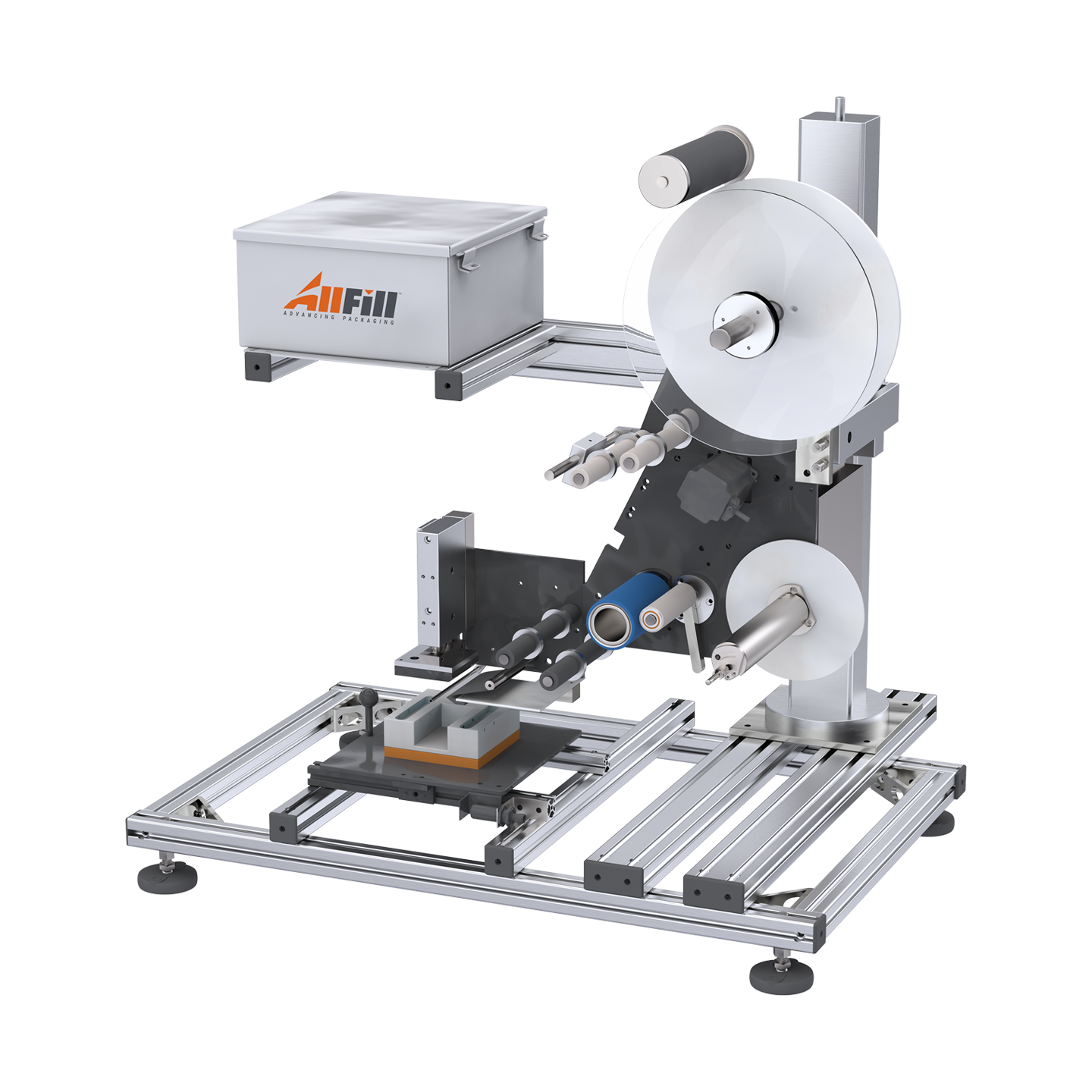

TABLE TOP SERIES

WELL SUITED FOR CONTAINERS AND PRODUCTS THAT HAVE UNUSUAL SHAPES AND MAY BE DIFFICULT TO HANDLE

Read More Read LessAll-Fill manufactures a wide variety of table top labeling machinery. These machines are well suited for containers and products that have unusual shapes and may be difficult to handle. With standard features such as removable tamp pads and adjustable product fixtures, the table top is versatile and easy to change over. We provide affordable base options and fully customized machines. These systems are an excellent choice for startups, first time buyers and operations with limited floor space.

-

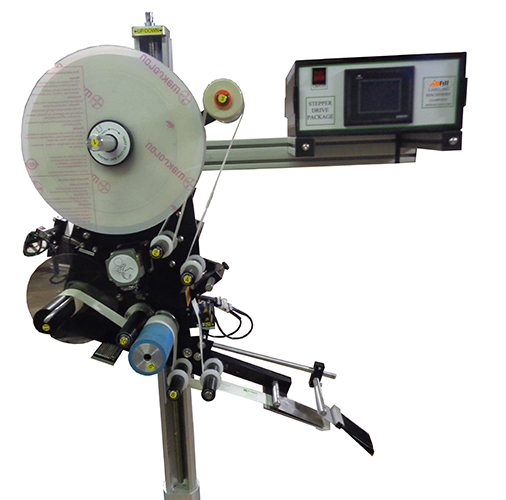

APPLICATORS SERIES

FEATURING SERIES/3 AND SERIES/6

Read More Read LessSERIES/3

Compact and versatile and can be top mounted, side-mounted or bottom mounted. As standard, it can handle labels up to 4 inches wide and has the option to go up to 6 inches wide. Construction. Aluminum & stainless steel Electrical 120 VAC Single Phase, Optional 220 Single or 3 Phase Size Options Standard labeling head sizes: 4" & 6" label width Options High-speed drive package Alarm package: low label, end of label and broken web detection Inspection / reject stations A variety of date lot coders

SERIES/6This is a versatile Printer / Applicator that will integrate with all major brands of print engines. The applicator is operated by a PLC. With a simple program change, the labeler may either print labels on demand or in batch mode. The labeling head may be configured for a wide variety of applications. These configurations include tamp apply, blown-on, tamp/blow, swing tamp, multi panel tamp, and our unique cage style application device allowing long narrow labels to be applied directly to the side of a product. A complete compliment of options is available to include an alarm package, and detection devices

Our Commercial Labeling Machines

If you manufacture or package a product of any kind, you probably need an industrial labeler for your facility. Our industrial labelers are ‘built to order’ from carefully engineered modular components. This allows us to build the basic platform of the labeling head in advance and assemble it to the customer’s exact specifications, improving the machines performance and reducing lead time. This piece of equipment can print, apply and dispense a variety of labels on a wide range of containers and packages made from plastic, steel, glass, aluminum and more. Ranging anywhere from round, flat panel, round square, top and bottom, bags, taper and non-tapered, and print and apply. In addition to supplying you with a packaging machine, we can also provide an industrial labeling machine that’s either fully automatic or semi-automatic.

What Industrial Labeling Systems Can Do For You

Industrial labeling systems are user friendly and developed to help your operation run efficiently and smoothly. All-Fill’s labeling systems can print, apply, and dispense labels successfully to various types of containers. Our machines feature color touch panel controls for quick set-up and easy changeovers. All adjustments to the label and label placement can be made when needed without interrupting the machine's operation. Label changeover and minor adjustments may be made without the use of tools making it easier to operate. If you are not sure what industrial labeling system is right for you, we will help you decide.

Benefits of working with All-Fill

-

Machines to fit your budget

Whether you are new to the packaging industry, getting ready to scale your operation or are an established packager, we have the variety of machines to fit your needs. From entry-level economy machines to high-speed lines, we engineer machines that meet your production demands and budget.

-

System Integration

In the world of packaging machinery, just about everything is custom. Our engineers are experts in customizing All-Fill equipment for maximum performance, versatility, and efficiency. We will help design, execute, and implement the perfect workflow or integrate with your existing equipment.

-

Product Experience

Auger fillers are equipped with different tooling to accommodate a variety of product characteristics. If your facility is running more than one product, you can customize a variety of tooling to make sure your equipment and product are running optimally.

-

Product Testing & Support

Every application has precise details that need to be evaluated and tested to find the perfect fit. We recommend sending sample products, bags, labels, and containers for free evaluation. As we continue to manufacture reliable equipment, we assure you we are here every step of the way.