Wrap Series

Labelers

Wrap Series

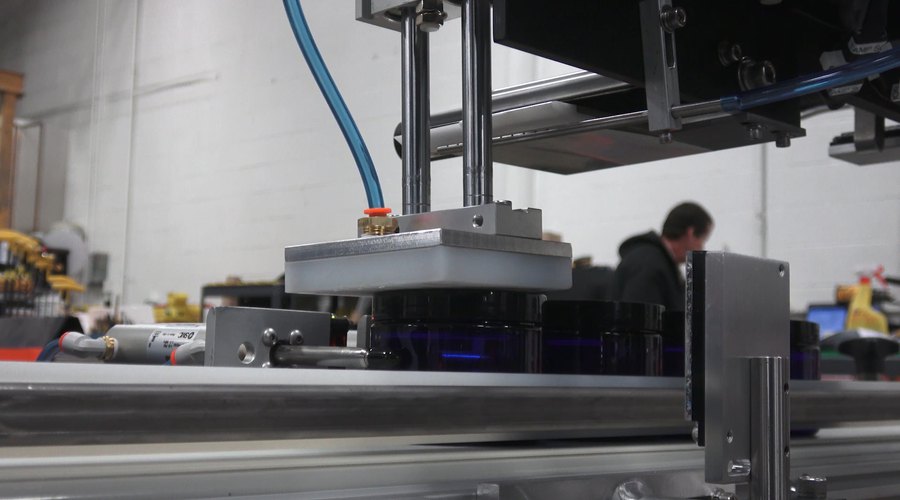

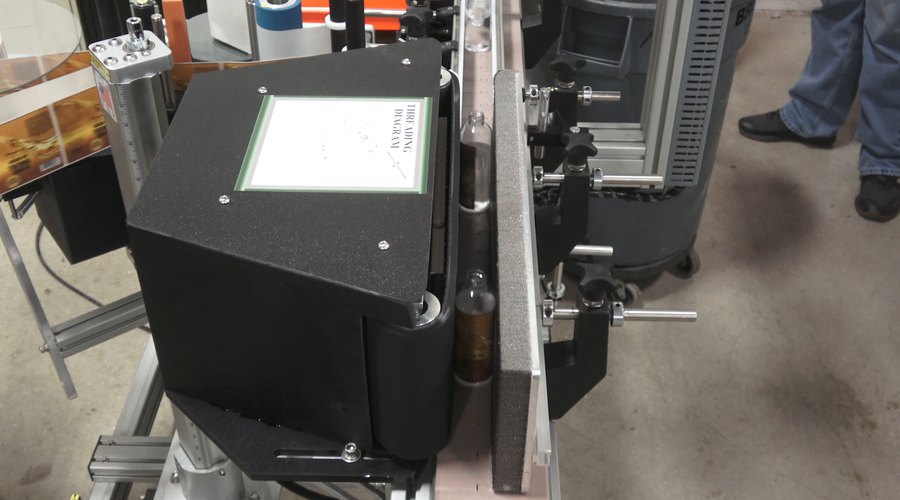

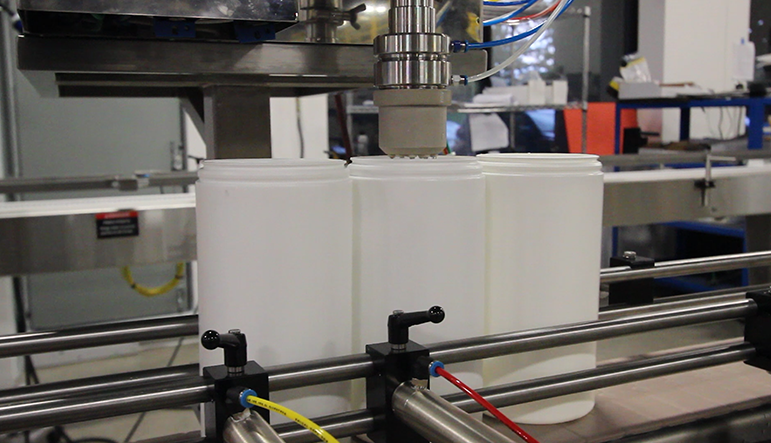

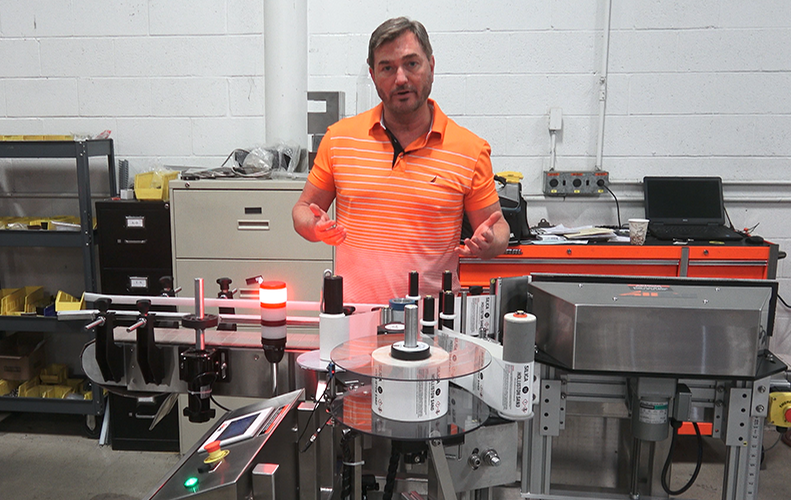

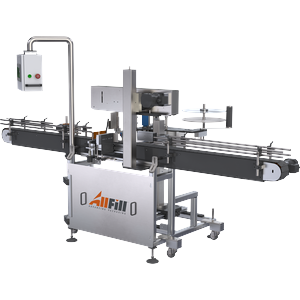

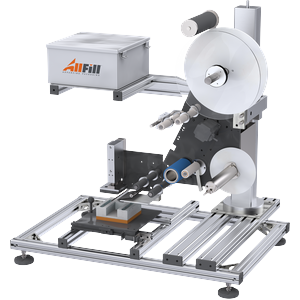

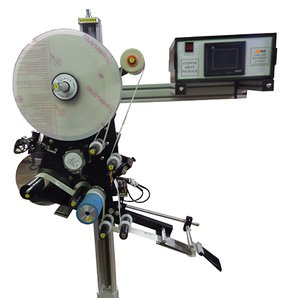

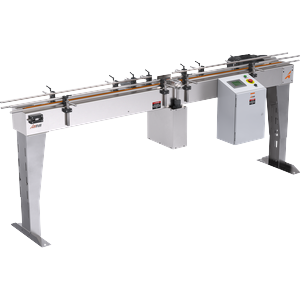

The Wrap Series of Labelers is designed to apply pressure sensitive labels to rigid and round containers, and square bottles with rounded edges. All-Fill labeling equipment has a variety of options including semi-automatic and automatic machines, featuring touch panel controls for quick and easy changeovers. There are also economical Wrap Labelers that are designed for limited volume production lines or start-up operations. We reduce the need for change parts with an open frame design that features a fully adjustable and versatile machine.

All of our Wrap Labeling Systems are designed with ease of operation in mind. All adjustments to the label and label placement can be made on the fly, without interrupting the machine's operation. Label changeover and minor adjustments may be made without the use of tools.

Specifications

-

Label SizesUp to 4" standard with options available for 6", 8" & 10", custom labeling heads up to 18”

-

Production RatesVariety of speed options available, Up to 300 ppm

-

Tool Size ChangeoverTool-less changeover, change parts may be required to accommodate different containers

-

Machine DimensionsConveyor based systems: 4 ft. wide by 6 ft. long. Table Top equipment: approximately 3 ft. wide by 2 ft. deep by 3 ft. tall

-

Roll DiameterStandard 12", options available for 16", 18" & 20"

-

Electrical120 V Single Phase, Optional 220 Single or 3 Phase

-

PneumaticWhen required 60 PSI, @ 3 SCFM

-

Standard FeaturesStepping motor drive with color touch panel controls for ease of set-up, 5ft. Long flat belt conveyor with fixed speed, A/C drive motor, Scaled head post for easy adjustment of applicator height

-

OptionsSemi-automatic and automatic options, Clear label sensor required for transparent labels, Fixed and Variable Speed Conveyors, Lead screw adjustment with scales for the in and out position of the labeling head, Complete alarm package to include end of web, low label, and broken web. Also available, a missing label on web alarm,A variety of date lot coders, Inspection station and reject systems, Many other options available

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Snap Top Containers

-

Spice Containers

-

Spray Bottles

-

Lip & Eye Liner Bottles

-

Plastic Cosmetic Jars

-

Round Edge Bottles

-

Nail Polish Bottles

-

Pill Bottles

-

Lip Balm & Lipstick Containers

-

Nutraceutical Containers

-

Glass Cosmetic Jars

-

Drink & Juice Bottles

-

Vape Pens

-

Liquid Drop Containers