Send a message

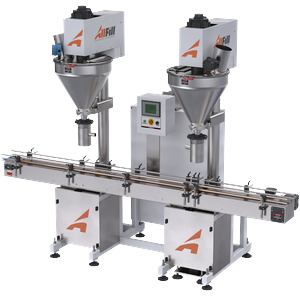

Series 500

Fillers

The Series 500 is a line of heavy duty, pneumatically operated, high capacity volumetric piston fillers for a wide range of liquids, creams, pastes, and gels. Our Piston Fillers can dispense particulates up to 7/8” diameter at production volumes of 8 oz. to 1 gallon per fill. A variety of nozzles, cutoffs, cylinder sets, and accessories are available to meet your specific requirements. All stainless steel construction and pneumatic operation ideal for wash-down environments, hazardous locations, and may incorporate up to 12 dispensing heads.

The Series 500 is suitable for accurate dispensing of most liquid or semi liquid products, and may be used for filling rigid containers and pouches. All contact parts are manufactured from stainless steel or suitable food grade plastics. Allowing them to be used for such diversified products such as food products, cosmetics & pharmaceuticals, home care products, and corrosive chemicals. Material may be handled hot or cold, and volumetric accuracy is usually within ±0.25%.

Specifications

-

Production RatesVaries dependent on fill size and amount of nozzles, 2, 4, 6, 8, 10 & 12 nozzle configurations available

-

FeaturesMulti-stroke control with counter controls. Container indexing to regulate container movement and positioning. Variable speed 8’ stainless steel conveyor; includes container indexing. Level control for consistent product re-supply. Footswitch for initiation of fill cycles. Air logic controls/air motor for hazardous locations.

-

Nozzle SizesA range of delivery nozzles allows exceptionally clean cut off of almost any liquid or semi liquid product.

-

Fill Volumes0.169 oz. to 1 gal., with solid particles up to 7/8”

-

Cylinder SizesVariety of sizes from .75" to 6.75"

-

Accuracy±0.5%, typical

-

Product SupplyPolished, stainless steel conical 13 gal. capacity hopper or 90° inlet adapter with 5’ of tubing for supply from bulk source

-

OptionsContainer indexing packages. Bottom-up filling. Insulated/heated hoppers. Tri-clover fittings for hopper and nozzle connections (pharmaceutical applications). Push button or footswitch initiation. Continuous recycling with toggle switch. Suck back design or positive cut-off. A range of portable stainless steel stands - low level, standard and heavy-duty with adjustable height. Multiple stroke mechanism for larger fills.

-

Options3 types of product valves available – standard rotary, large rotary and check valve, optional sub-surface filling mechanism and nozzle for filling foaming products.

-

ControlsFill Volume: stroke adjustment knob at rear of unit, fill & recharge speed: adjustment, Initiation: footswitch initiation or automatic

-

Pneumatic120 PSI, 10 SCFM

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Apple Sauce

-

Jams / Jellies

-

Tomato Paste

-

Motor Oil

-

Ketchup

-

Mustard

-

Pesto / Relish

-

Peanut Butter

-

Cosmetic Pastes

-

Bubble Bath

-

Nail Polish

-

Body Scrubs

-

Yogurt

-

Ointments / Medicine

-

Petroleum Products

-

Shampoo & Hair Gel

-

Food Sauces

-

Building Adhesives

-

Epoxies / Adhesives

-

Liquid Wax

-

Lotions

-

Glue

-

Raw Dough

-

Honey

-

Cooking Oil

-

Hummus

-

Pâté

-

Salad Dressings

-

Butter / Margarine

-

Fruit Juices