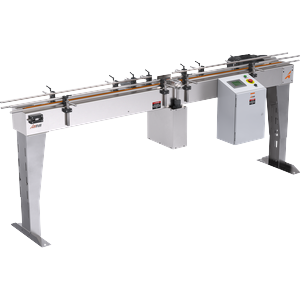

Model BS Box Filling System

Fillers

All-Fill’s Model BS Box Auger Filling System fills large boxes with products. This is a “bulk and dribble” application. When the empty box is in place, a tare weight is established. A pneumatic lift then lifts the empty box from the scale to its bulk-fill position. A bottom-up fill occurs, ensuring that the amount of dust caused by the process is minimized.

A dust hood is also provided to assist in dust control. As the bulk fill is in progress, the lift lowers to the scale at a slower speed. A bulk weight is taken at the scale. The lift then raises back up and the bottom-up dribble fill commences. The lift again lowers to the scale, and a final weight is taken. If it is underweight, a second dribble fill occurs. The scale also has a “real-time” weight function to guarantee flexibility and accuracy.

Specifications

-

Construction

-

Production Rates

-

Control Features

-

Storage

-

Hopper Capacity

-

Electrical Requirements

-

Pneumatic Requirements

-

Changeovers

-

Options

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Fertilizer Pellets

-

Toner Powder

-

Cat Litter

-

Small Pet Food

-

Whole & Ground Coffee

-

Sugar

-

Jimmies & Sprinkles

-

Plant Foods

-

Food Powders

-

Plastic Granules

-

Ground Spices

-

Flake Spices

-

Fine Cut Tobacco

-

Flour Powder

-

Whole & Ground Pepper

-

Detergent Powder

-

Infant Formula

-

Cake Mix

-

Pancake Mix

-

Cement Powder

-

Cocoa Powder

-

Matcha Powder

-

Cosmetic Powder

-

Curry Powder

-

Protein Powders

-

Turmeric Powder

-

Parsley & Oregano

-

Grains

-

Seeds

-

Chia Seeds

-

Grass & Fennel Seeds

-

Salt Products

-

Rice Products

-

Lentils

-

Breadcrumb

-

Brown Sugar